In the pursuit of greener, more efficient steel production, electric arc furnaces (EAF) equipped with ultra-large diameter graphite electrodes have emerged as pivotal technology enablers. Specifically, graphite electrodes exceeding 500mm in diameter are transforming EAF steel recycling processes by enhancing arc stability, extending electrode lifespan, and significantly reducing operational costs. This article delves into the technical advantages, installation best practices, and environmental benefits associated with these high-performance electrodes, offering actionable insights for technical managers and decision-makers in steel manufacturing.

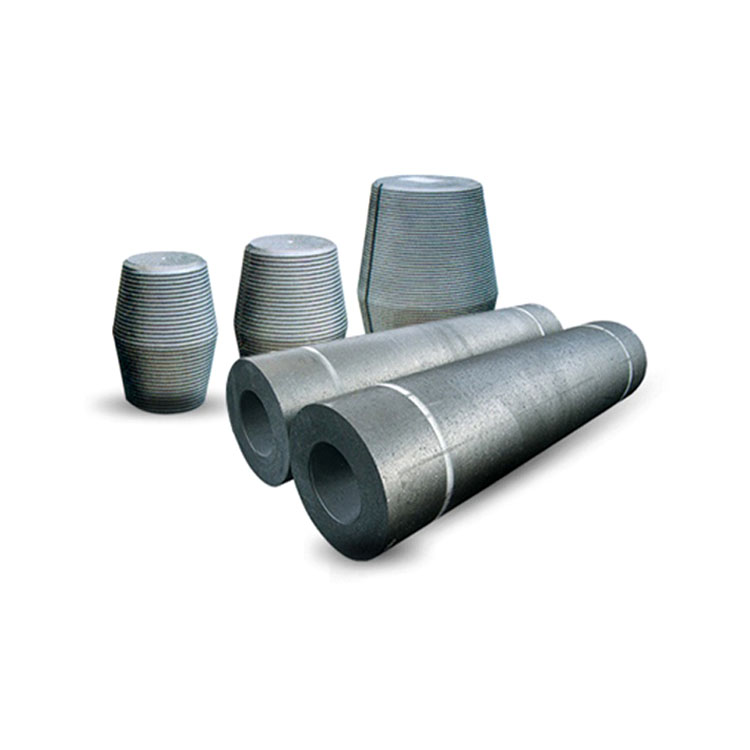

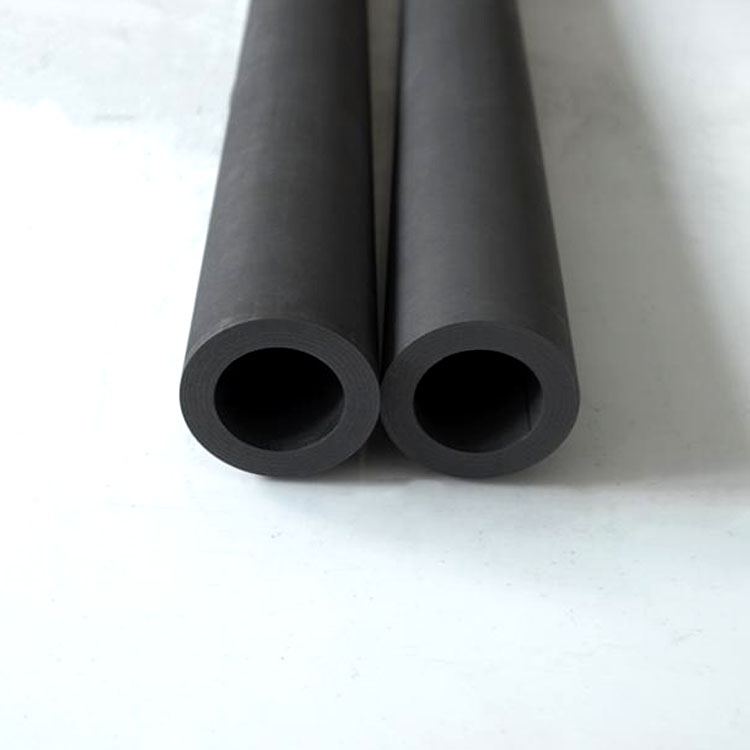

The core innovation with ultra-large diameter graphite electrodes lies in their dimensional scale and optimized thread structure. Increasing the electrode diameter beyond 500mm amplifies the current-carrying capacity, which leads to a more stable and concentrated electric arc inside the furnace. This structural upgrade results in higher melting efficiency and better energy conversion.

Moreover, the use of enhanced thread designs, such as rolled threads with increased contact surface area, reduces electrical resistance and mechanical wear during operation. This synergy of size and threading decreases electrode breakage rates by approximately 15-20%, based on aggregated industry data, and boosts melting speed by up to 12% compared to conventional electrodes.

| Parameter | Standard Diameter Electrode (400mm) | Ultra-Large Diameter Electrode (≥500mm) |

|---|---|---|

| Current Carrying Capacity (kA) | 25-35 | 40-50 |

| Electrode Lifespan (hours) | 120-150 | 180-200 |

| Melting Efficiency Improvement | - | ~12% |

| Breakage Rate Reduction | - | 15-20% |

While the technical merits are clear, the successful deployment of ultra-large diameter graphite electrodes hinges on meticulous installation and maintenance protocols. Operators should prioritize proper alignment during assembly to avoid thread damage and ensure full contact, a step critical to preserving the electrical and mechanical integrity over time.

Routine inspections using thermal imaging and ultrasonic testing enable early detection of partial cracks or degradation, allowing preventative maintenance that can extend electrode life by at least 30%, as demonstrated by field case studies.

Replacing electrodes only at optimal wear thresholds rather than on fixed schedules reduces unnecessary downtime and procurement costs. Furthermore, cleaning the electrode surfaces and boreholes regularly minimizes contamination-induced resistive losses, which typically account for 5-7% efficiency drops if neglected.

A global steel producer adopting our ultra-large diameter graphite electrodes reported a 35% increase in electrode lifespan and a 10% reduction in electricity consumption within the first operational year. This improvement translated to annual energy savings surpassing USD 120,000, demonstrating tangible cost benefits alongside operational efficiency.

These gains were attributed to a combined approach leveraging electrode design optimization, enhanced installation fidelity, and disciplined maintenance schedules. The operator remarked: “Switching to ultra-large diameter electrodes not only boosted our furnace uptime but aligned perfectly with our sustainability goals.”

Ultra-large diameter graphite electrodes contribute significantly to the steel industry's green transformation. By enhancing melting efficiency and reducing electrical resistive losses, they lower overall power consumption per ton of steel produced. Industry reports estimate that adopting these electrodes can cut carbon emissions by 8-12% in EAF steelmaking operations.

This aligns with global directives targeting carbon neutrality in heavy industries by 2050. Moreover, reduced electrode replacement frequency decreases waste generation and minimizes the environmental footprint of electrode production itself.