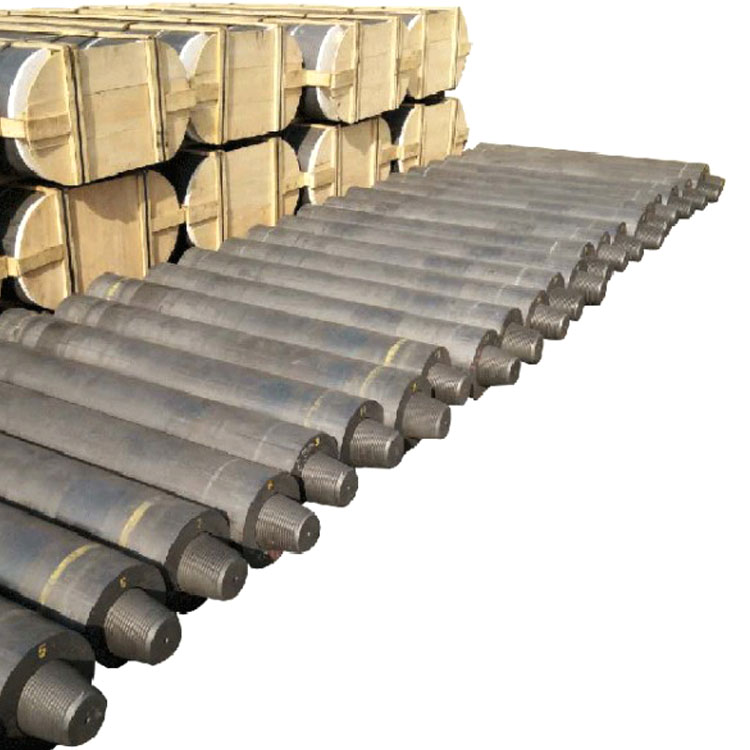

The steel industry's ongoing commitment to sustainable and efficient production methods has brought electric arc furnace (EAF) technology to the forefront. Central to optimizing EAF operations is the use of graphite electrodes, particularly ultra-large diameter electrodes exceeding 500 mm. These advanced electrodes significantly improve arc stability, melting efficiency, and environmental performance in steel recycling processes. This article delves into the technical nuances of ultra-large diameter, ultra-high power graphite electrodes and their transformative impact on modern EAF steelmaking.

Increasing the diameter of graphite electrodes enables the conduction of higher electrical currents, directly enhancing the melting power of EAFs. Typical electrodes used in conventional steelmaking range from 350 mm to 450 mm in diameter, whereas ultra-large electrodes surpassing 500 mm enable current capacities upward of 25,000 amperes. This leap facilitates:

Beyond size, the internal architecture and material quality of graphite electrodes play crucial roles. Innovations include:

| Design Feature | Benefit |

|---|---|

| Fine-Grain Isotropic Graphite Composition | Uniform electrical conductivity and mechanical strength, reducing electrode degradation. |

| Precision Threading and Connection Geometry | Improved mechanical joint stability facilitates fast and secure electrode installation and replacement. |

| Optimized Porosity and Density Control | Minimizes oxidation rates to extend electrode lifespan even under demanding thermal cycles. |

Reliable performance of ultra-large diameter electrodes depends on stringent operational discipline during installation and maintenance:

Industry experience confirms that following these practices can increase electrode operational life by approximately 20-30%, significantly impacting continuous EAF steel production and product quality.

The integration of ultra-large diameter graphite electrodes contributes decisively toward greener steel production. Key benefits include:

A leading steel manufacturer implemented 550 mm diameter ultra-high power graphite electrodes in their EAF operations, resulting in:

| Performance Metric | Before Upgrade | After Upgrade | Improvement |

|---|---|---|---|

| Melting Throughput (tons/hour) | 25 | 29 | +16% |

| Electrode Consumption Rate (kg/ton) | 2.1 | 1.7 | -19% |

| Energy Consumption (kWh/ton) | 440 | 394 | -10.5% |

These gains directly translated into increased production capacity and substantially lowered operational costs, underscoring the value of ultra-large diameter graphite electrodes in modern EAF steelmaking.

For technical managers and maintenance teams seeking to enhance operational continuity and electrode longevity, leveraging detailed whitepapers, step-by-step installation guides, and in-depth video tutorials is highly recommended. Adopting a proactive approach toward electrode management will safeguard steel quality and promote sustainable operations.