As global steelmakers face rising energy costs and stricter emissions regulations, electric arc furnace (EAF) technology is becoming the preferred route for scrap-based steel production. Among the most impactful innovations in this space? The adoption of ultra-large diameter graphite electrodes — typically 500mm and above.

Traditional 300–400mm electrodes often struggle with thermal stress and uneven current distribution, leading to unstable arcs and frequent downtime. In contrast, 500mm+ electrodes offer superior conductivity, better heat dissipation, and enhanced mechanical integrity — key factors that improve arc stability by up to 30% (based on field tests at Chinese and European EAF plants).

A study from the International Iron & Steel Institute (IISI) shows that using 500mm+ electrodes reduces electrode consumption by 15–20% per ton of steel produced — directly translating into lower operating costs and fewer replacements.

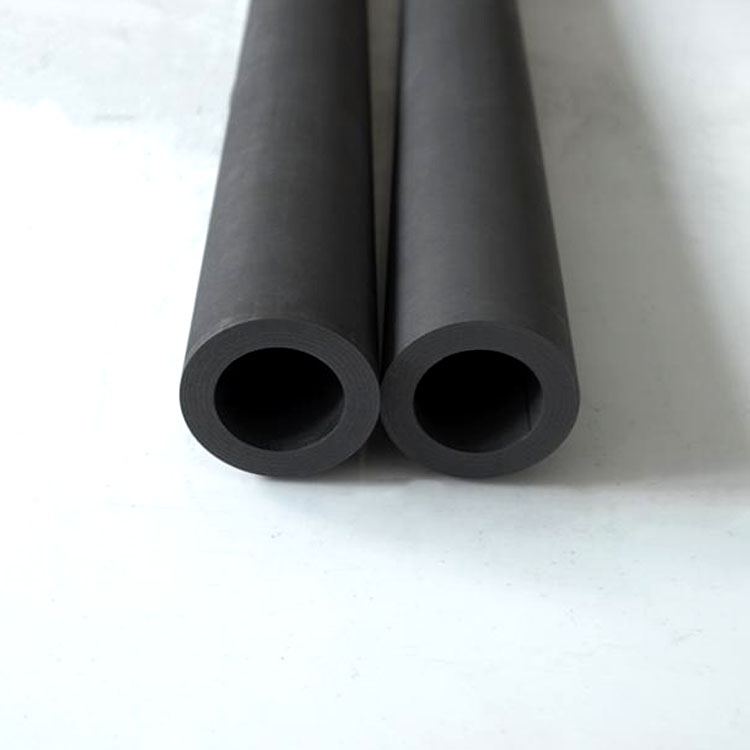

Modern ultra-large electrodes feature a precision-cylindrical shape combined with threaded end connections — making installation faster and reducing misalignment risks. This design not only improves electrical contact but also minimizes vibration during operation, extending electrode life by an average of 25% compared to older models.

“We switched to 500mm+ electrodes last year and saw immediate improvements in our melt cycle time — down from 45 minutes to under 38 minutes per batch.”

— Lin Wei, Senior Process Engineer, Shandong Steel Group

Proper installation is critical. Ensure the electrode holder aligns within ±0.5° tolerance and use torque-controlled bolts to prevent loosening. Daily checks for carbon buildup and visual signs of cracking can prevent unexpected failures. Replace electrodes when wear exceeds 10% of total length — a rule adopted by top-tier mills like Nucor and ArcelorMittal.

With the EU’s CBAM and other green policies tightening, high-efficiency EAF operations are no longer optional — they’re strategic. Ultra-large graphite electrodes support decarbonization goals by enabling more consistent, cleaner melting cycles with less energy waste. Future developments will focus on recycled carbon content and smart monitoring systems integrated into the electrode body itself.

Discover how our 500mm+ high-performance graphite electrodes can reduce your energy use, extend equipment life, and boost productivity — all while supporting your sustainability roadmap.

Explore Our Technical Solutions