As global steelmakers shift toward sustainable, energy-efficient processes, the demand for high-power graphite electrodes (HPGEs) is surging—especially in electric arc furnace (EAF) operations. These aren’t just components; they’re strategic assets that directly impact your plant’s efficiency, cost structure, and environmental footprint.

At the heart of every high-performance HPGE lies premium needle coke—a raw material known for its exceptional purity and crystalline alignment. Compared to standard graphite electrodes, needle coke-based products offer up to 15% higher conductivity, reducing resistive losses during melting cycles. This translates into measurable savings: one European EAF mill reported a 7–10% drop in kWh/tonne of steel produced after switching to our HPGEs.

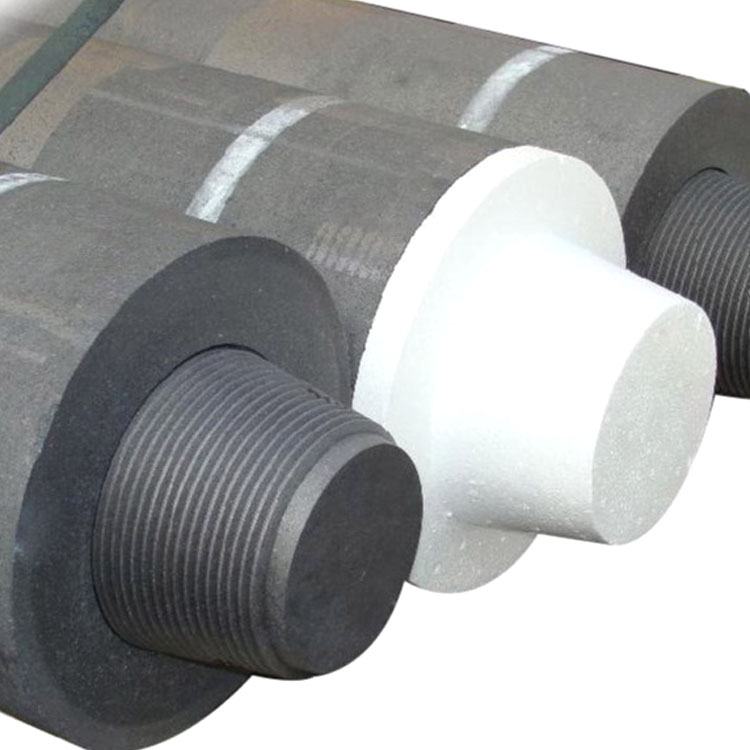

But it's not just about conductivity. The precision machining—particularly the cylindrical geometry and threaded ends—ensures consistent contact resistance across connections. In fact, field data shows that our electrodes reduce connection-related downtime by over 25% compared to conventional designs.

“The real game-changer isn’t just the electrode itself—it’s how reliably it performs under extreme thermal stress.”

— Dr. Lena Müller, Senior Materials Engineer at Fraunhofer Institute for Metal Forming

With EU Green Deal regulations tightening carbon intensity standards and China mandating EAF capacity expansion, the market for advanced HPGEs is projected to grow at 8.3% CAGR through 2030. Buyers who act now gain early access to technology that boosts both compliance and competitiveness.

Our customers—ranging from mid-sized mills in Mexico to large integrated producers in South Korea—have consistently seen:

We don’t sell electrodes—we enable smarter, cleaner steel production. Whether you're optimizing an existing EAF line or planning a new facility, our team provides technical support, on-site testing, and tailored recommendations based on your specific process parameters.

In a sector where margins are tight and sustainability is non-negotiable, choosing the right electrode can mean the difference between being a follower—and leading the transition to next-gen steelmaking.

Get a free performance analysis for your EAF operation—no obligation, just actionable insights.

Download Our Free EAF Optimization Guide