In the realm of steel production, the ultra - high power electric arc furnace (EAF) with a diameter exceeding 500 millimeters stands as a cornerstone of modern manufacturing. The selection of graphite electrodes in these furnaces is a critical decision that directly impacts furnace efficiency and operational costs. This guide aims to provide in - depth insights into optimizing electrode performance based on furnace type and current density.

Needle coke is a key raw material for high - performance graphite electrodes. Its unique molecular structure endows graphite electrodes with excellent conductivity and thermal stability. Compared to traditional coke, needle coke has a highly oriented lamellar structure, which allows electrons to move more freely, thus significantly improving the electrical conductivity of the electrode. In terms of thermal stability, needle coke can withstand high - temperature environments in the EAF without significant deformation or damage. For example, in a high - temperature environment of over 3000°C, electrodes made from needle coke can maintain their structural integrity, ensuring stable operation of the furnace.

When it comes to current density, electrodes made from needle coke can handle higher current loads. In an EAF with a current density of over 20 A/cm², needle coke electrodes can conduct electricity more efficiently, reducing energy loss during the current transmission process. This directly translates into energy savings and improved furnace efficiency. A comparison between traditional electrodes and high - power electrodes made from needle coke in a thermal cycle test shows that traditional electrodes experience a 10 - 15% increase in resistivity after multiple thermal cycles, while needle coke electrodes only show a 3 - 5% increase.

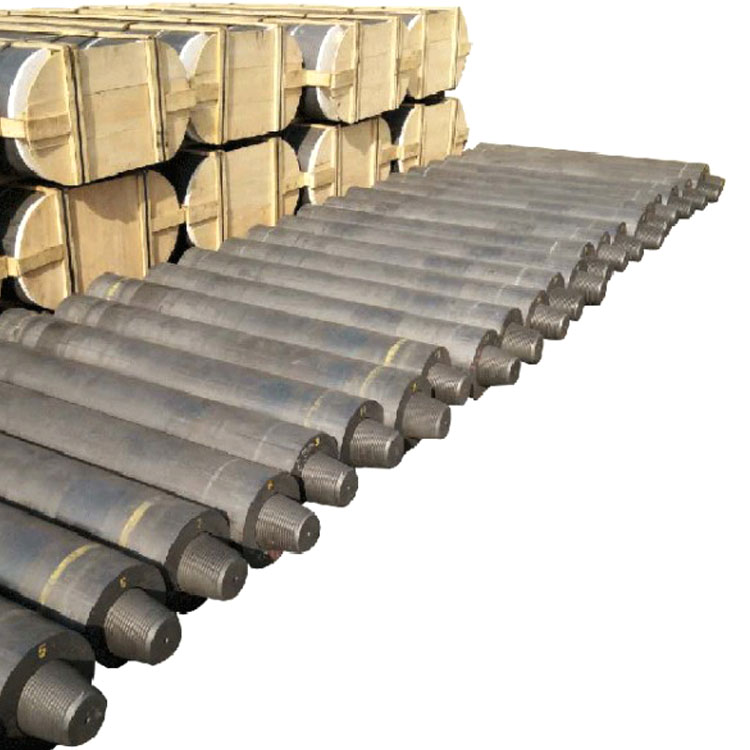

Precision machining is another crucial factor in optimizing electrode performance. High - precision machining ensures that the electrode has a uniform diameter and smooth surface, which is essential for stable current conduction. Any irregularities on the electrode surface can cause uneven current distribution, leading to local overheating and potential electrode damage. For example, a deviation of more than 0.5 mm in the electrode diameter can result in a 5 - 10% reduction in current - carrying capacity.

The machining accuracy of the electrode end is also of great importance. A well - machined electrode end can ensure a tight fit with the electrode connector, reducing contact resistance. In a real - world scenario, a steel mill found that by improving the machining accuracy of the electrode end, the contact resistance was reduced by 12%, which in turn improved the overall efficiency of the EAF.

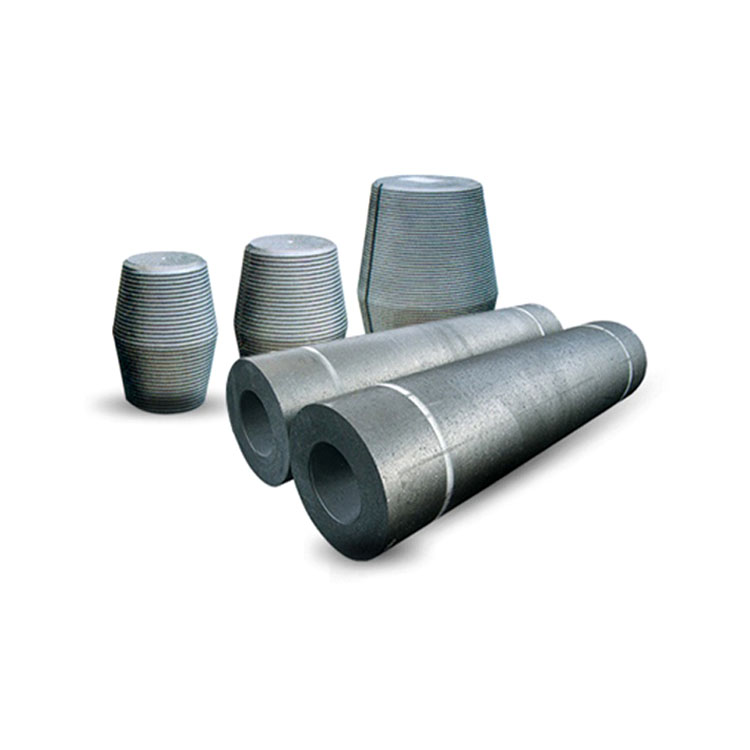

The end thread structure of the graphite electrode plays a vital role in enhancing mechanical strength and joint reliability. A well - designed thread structure can evenly distribute the mechanical stress during electrode connection, preventing the electrode from breaking or loosening during operation. For example, a special tapered thread design can increase the contact area between the electrode and the connector, improving the joint's mechanical strength by 20 - 30% compared to traditional straight - thread designs.

In terms of current conduction, a good thread connection design can also ensure a continuous and stable current path. By reducing the contact resistance at the joint, the overall energy loss in the electrode system can be minimized. In a test, a steel mill replaced the traditional electrode connection with a new thread - connection design and found that the energy consumption was reduced by 8% due to the improved current conduction at the joint.

Selecting the right electrode also requires considering the actual working conditions of the EAF. Different furnace types have different requirements for electrode performance. For example, a DC EAF has different current distribution characteristics compared to an AC EAF. In a DC EAF, the electrode needs to have better unidirectional conductivity, while in an AC EAF, the electrode needs to adapt to the alternating current changes. Therefore, when selecting electrodes, it is necessary to match the electrode parameters with the specific furnace type and current density.

Another aspect is the matching of the electrode to the production rhythm of the steel mill. In a steel mill with a high - frequency production rhythm, the electrode needs to have better thermal shock resistance to withstand the rapid temperature changes during the start - stop process of the furnace. By matching the electrode to the actual working conditions, the service life of the electrode can be extended, and the overall production cost can be reduced.

Many steel mills have achieved significant benefits by optimizing electrode selection. For instance, a large - scale steel mill in Europe replaced its traditional electrodes with high - power needle coke electrodes. After the replacement, the energy consumption of the EAF was reduced by 15%, and the production efficiency was increased by 12%. This not only saved a large amount of energy costs but also improved the overall competitiveness of the steel mill in the market.

Another steel mill in Asia optimized the electrode connection design and improved the machining accuracy of the electrodes. As a result, the electrode breakage rate was reduced from 3% to 1%, and the maintenance cost of the furnace was significantly reduced. These real - world cases demonstrate the practical value of optimizing electrode selection.

To help steel mills better maintain and evaluate the performance of electrodes, here is a simple inspection checklist:

| Inspection Item | Inspection Method | Acceptance Criteria |

|---|---|---|

| Electrode diameter | Use a caliper to measure at multiple points | Deviation within ±0.5 mm |

| Surface smoothness | Visual inspection and touch | No obvious scratches or bumps |

| Thread connection | Check for tightness and alignment | No looseness or misalignment |

| Electrode resistivity | Use a resistivity meter | Within the specified range |

Optimizing the selection of graphite electrodes based on furnace type and current density is a complex but rewarding task. By focusing on raw material selection, precision machining, end - thread structure, and actual working - condition matching, steel mills can significantly improve furnace efficiency, reduce energy consumption, and lower production costs. If you are looking to enhance the performance of your EAF and achieve more efficient and sustainable steel production, click here to learn more about our high - performance graphite electrodes.