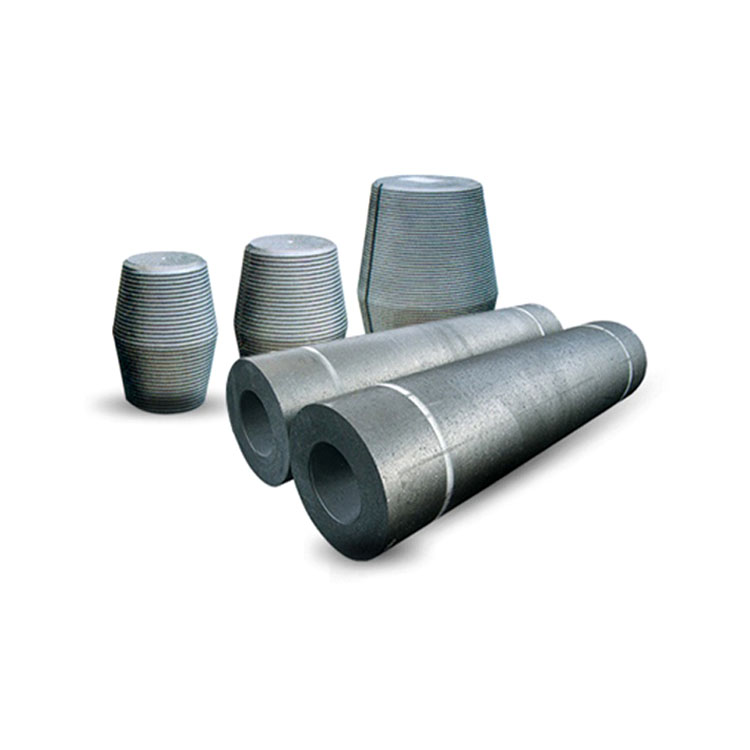

Have you ever encountered a situation where a steel plant suffered significant losses due to furnace shutdown caused by electrode failure? In the operation of ultra-high power electric arc furnaces (EAFs), the selection of graphite electrodes directly affects furnace efficiency and energy consumption. This article will delve into the key points of graphite electrode selection for ultra-high power EAFs to help you make more informed decisions.

Let's start with a real - life scenario. A steel mill once faced a major setback when an electrode failure led to an unexpected furnace shutdown. This not only caused a halt in production but also resulted in substantial financial losses. Such incidents are not uncommon in the steel industry, highlighting the critical importance of proper graphite electrode selection.

Graphite electrodes can be made from different raw materials, with needle coke being a high - performance option. Needle coke has unique properties that set it apart from ordinary graphite. In terms of electrical conductivity, needle coke - based graphite electrodes can offer up to 20% better conductivity compared to those made from ordinary graphite. This means more efficient power transfer within the furnace, reducing energy waste.

When it comes to thermal stability, needle coke also shines. The anti - thermal shock performance of needle coke graphite electrodes is significantly better. In high - temperature environments within the EAF, ordinary graphite electrodes may crack or break due to thermal stress, while needle coke electrodes can withstand these extreme conditions more effectively. For example, in a test, needle coke electrodes showed a 30% lower rate of thermal - shock - related damage compared to ordinary graphite electrodes.

| Raw Material | Electrical Conductivity | Anti - Thermal Shock Performance |

|---|---|---|

| Needle Coke | Up to 20% better than ordinary graphite | 30% lower rate of thermal - shock - related damage |

| Ordinary Graphite | Lower | Higher risk of cracking and breaking |

The machining precision of graphite electrodes and the design of the end - thread structure are also crucial factors. High - precision machining ensures that the electrodes have a more uniform shape, which is essential for stable current distribution. The end - thread structure affects the connection reliability between electrodes and the current density distribution at the connection point.

A well - designed thread structure can improve the mechanical strength of the connection and reduce the risk of electrode disconnection during operation. For example, a new type of thread design can increase the connection strength by 15%, ensuring a more stable current flow and reducing the likelihood of local overheating.

One steel plant decided to replace its old electrodes with high - stability needle coke graphite electrodes. After the replacement, they were able to reduce their energy consumption per ton of steel by 15%. This not only saved them a significant amount of money on energy costs but also made their production process more environmentally friendly. Another customer reported that after using our recommended electrodes, they experienced fewer furnace shutdowns, increasing their overall production efficiency by 10%.

Some people may think that larger - diameter electrodes are always better. However, this is a common misconception. In fact, the selection of electrode diameter should be based on the furnace type and current density. Using an electrode with an inappropriate diameter can lead to uneven current distribution, increased energy consumption, and even electrode failure. It is essential to match the electrode diameter with the specific requirements of the EAF.

To help you with the daily maintenance of graphite electrodes, we provide a simple electrode status inspection checklist. This checklist includes items such as electrode surface condition, thread wear, and connection tightness. Regularly using this checklist can help you detect potential problems early and take timely measures to avoid electrode failure.

If you want to learn more about optimizing the selection of ultra - high power graphite electrodes for your EAF and take your steel production to a new level of efficiency and sustainability, click here to explore our comprehensive solutions!