Elevated temperature levels in steel ladle shell walls pose significant challenges to the steelmaking industry — jeopardizing operational safety and inflating energy consumption. Managing this thermal load effectively is paramount. Enter the Sunrise Vermiculite Steel Ladle Insulation Board, engineered as an innovative third-layer insulation solution that revolutionizes heat retention and shell cooling strategies. Leveraging its low thermal conductivity, superior thermal stability, and chemical resistance, this technology achieves ladle shell temperature reduction by up to 50°C, while enabling insulation thickness reduction of 10 to 18 mm. The resultant benefits manifest as measurable energy savings, enhanced safety margins, and improved steel quality.

Steel ladles inherently operate under extreme thermal conditions, with shell temperatures commonly exceeding safety thresholds. Overheated ladle shells increase the risk of structural damage and refractory failure, threatening personnel safety and causing costly downtime. Moreover, excessive heat loss translates directly into higher fuel consumption for reheating processes, contributing to avoidable CO2 emissions and operational costs. These pain points call for advanced insulation materials capable of superior heat retention without compromising mechanical integrity or adding bulk.

Conventional insulation layers—typically consisting of standard refractory bricks or thick ceramic fiber blankets—exhibit several drawbacks:

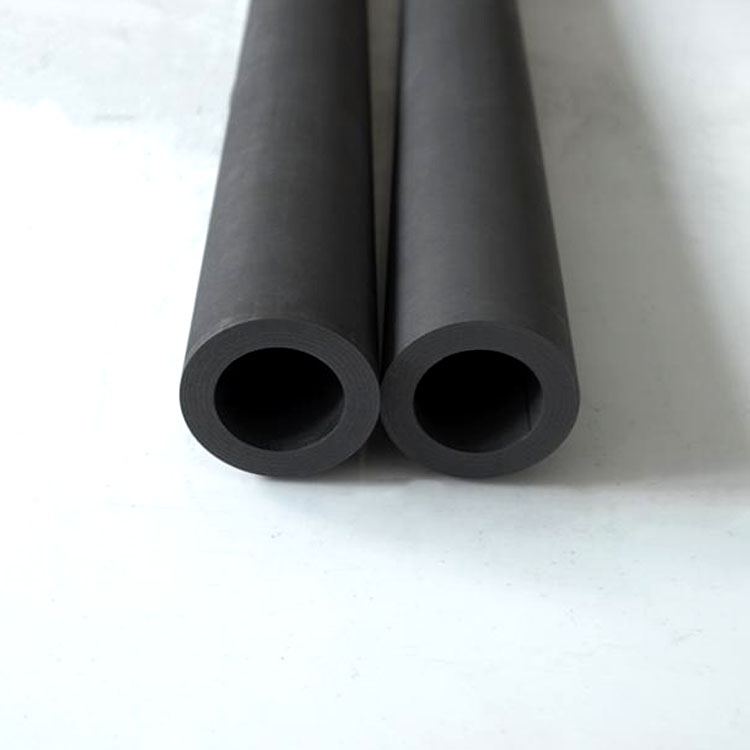

The Sunrise vermiculite insulation board is designed as a high-performance third-layer addition beyond primary refractory linings. Its engineered composition delivers:

| Feature | Performance Metric | Benefit |

|---|---|---|

| Thermal Conductivity | ≤ 0.12 W/m·K at 1000°C | Superior heat insulation reducing heat loss |

| Thermal Stability | Stable up to 1200°C without degradation | Long lifespan under severe thermal cycling |

| Chemical Resistance | Highly resistant to slag and metal vapors | Minimized corrosive wear, preserving shell integrity |

| Thickness Reduction | 10–18 mm compared to conventional 30+ mm layers | Space-saving, easier installation and retrofit |

These combined factors empower the vermiculite insulation board to sharply minimize thermal losses without increasing insulation thickness, making the third-layer solution exceptionally practical.

Case Study – Xingtai Steel Plant (China): After applying the Sunrise vermiculite third-layer insulation on their ladle shells, the plant recorded an average shell temperature drop of 45°C, leading to a reduction of 120 tons monthly in standard coal consumption. This translated into annual energy savings exceeding USD 200,000 and significantly improved workplace safety margins due to cooler shell surfaces.

This quantitative evidence highlights the dual-effect excellence of the technology: cutting energy costs while fortifying operational safety. Facilities adopting this solution report consistent improvements in refractory lifespan and casting quality, correlating directly with the controlled thermal environment.

Optimal performance of Sunrise vermiculite boards requires meticulous adherence to installation and maintenance protocols:

Following these best practices extends the operational lifetime of the insulation layer and maximizes energy efficiency gains.

In an era prioritizing decarbonization, every innovation saving energy and CO2 emissions is vital. The reduced heat loss from Sunrise’s vermiculite technology translates directly into lower fossil fuel consumption and carbon footprint per ton of steel produced. Integrating this solution helps steel companies meet increasingly stringent environmental regulations and corporate sustainability goals — empowering the industry to forge a greener future.

Empower your steel plant with third-layer vermiculite insulation technology — discover how to achieve energy savings and safer operations today.