In the realm of electric arc furnace steel recycling processes, super - large diameter graphite electrodes play a pivotal role. This article will comprehensively explore their core working principles, the ways they enhance electric arc furnace efficiency, and practical operation guidelines.

The performance of super - large diameter graphite electrodes is determined by multiple factors. First, their excellent electrical conductivity ensures a stable current flow during the arc - forming process. High - quality graphite materials can reduce resistance, thereby minimizing energy loss. For example, compared with ordinary electrodes, super - large diameter graphite electrodes can reduce electrical resistance by about 10% - 15%, which significantly improves energy utilization efficiency.

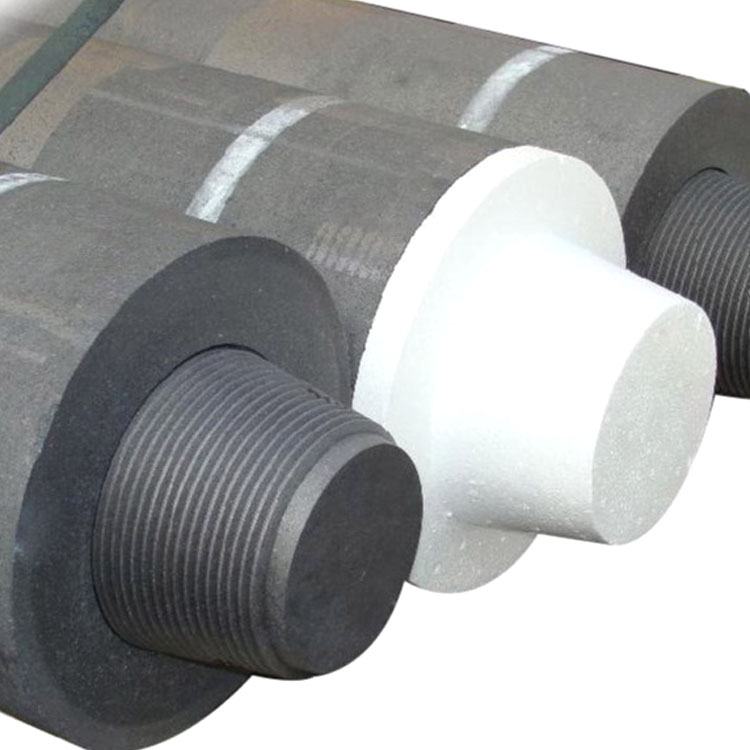

Thermal stability is another crucial characteristic. The ability to withstand high temperatures without deformation or breakage is essential for maintaining arc stability. In the high - temperature environment of an electric arc furnace, these electrodes can maintain their structure intact, ensuring continuous and efficient operation. Additionally, the threaded connection structure of the electrode also contributes to arc stability. A well - designed threaded connection can ensure a tight fit between electrodes, reducing the risk of arc interruption.

In EAF applications with a power of 500mm or more, the size advantage of super - large diameter graphite electrodes becomes particularly prominent. Larger diameters can increase the contact area between the electrode and the furnace charge, which enhances energy conduction efficiency. According to relevant research, in a 500mm EAF, using super - large diameter electrodes can increase the energy conduction efficiency by about 15% - 20% compared with smaller - diameter electrodes.

This improvement in energy conduction directly leads to an increase in the melting rate of the furnace charge. Faster melting means shorter production cycles and higher production efficiency. For steel mills, this translates into increased output and reduced production costs.

Proper installation, maintenance, and replacement of electrodes are crucial for their performance and service life. When installing electrodes, it is necessary to follow strict installation specifications to ensure correct alignment and tight connection. For example, the torque of the threaded connection should be within a specified range to prevent loosening during operation.

In terms of daily maintenance, regular inspection of electrode wear, surface cracks, and connection conditions is necessary. Cleaning the electrode surface can also improve its performance. When it comes to replacement, it is important to accurately judge the replacement time. Generally, when the electrode diameter is reduced to a certain extent or there are serious internal damages, replacement should be carried out in time. Here is a simple table summarizing the key points:

| Operation | Key Points |

|---|---|

| Installation | Follow installation specifications, ensure correct alignment and proper torque of threaded connection |

| Maintenance | Regular inspection of wear, surface cracks, and connection; clean the surface |

| Replacement | Judge replacement time based on diameter reduction and internal damage |

By comparing typical steel mills' cases, we can clearly see the actual effects of using super - large diameter graphite electrodes. In a certain steel mill, after using these electrodes, the electrode service life increased by about 20% - 30%, energy consumption decreased by about 12% - 18%, and carbon emissions were also significantly reduced. These data clearly demonstrate the advantages of super - large diameter graphite electrodes in improving production efficiency and environmental protection.

In the context of global green and low - carbon development, high - quality super - large diameter graphite electrodes have strategic value in the transformation of green and low - carbon metallurgy. They can not only improve production efficiency but also reduce energy consumption and carbon emissions, which is in line with the development trend of the steel industry towards environmental protection and high efficiency.

In conclusion, super - large diameter graphite electrodes have significant advantages in improving the efficiency of electric arc furnaces and promoting green metallurgy. If you want to learn more about product solutions and how these electrodes can benefit your production, click here to visit our official website's technical section.