Extra-large diameter (500mm+) graphite electrodes play a crucial role in the electric arc furnace steel recycling process. Compared with traditional small-diameter electrodes, they have significant advantages in enhancing arc stability and heat conduction efficiency. The larger cross - sectional area of extra - large diameter electrodes allows for a more uniform distribution of current, reducing the risk of arc flicker. For example, in a typical steel recycling arc furnace, traditional small - diameter electrodes may experience arc instability up to 15% of the time during operation, while extra - large diameter electrodes can reduce this instability to less than 5%.

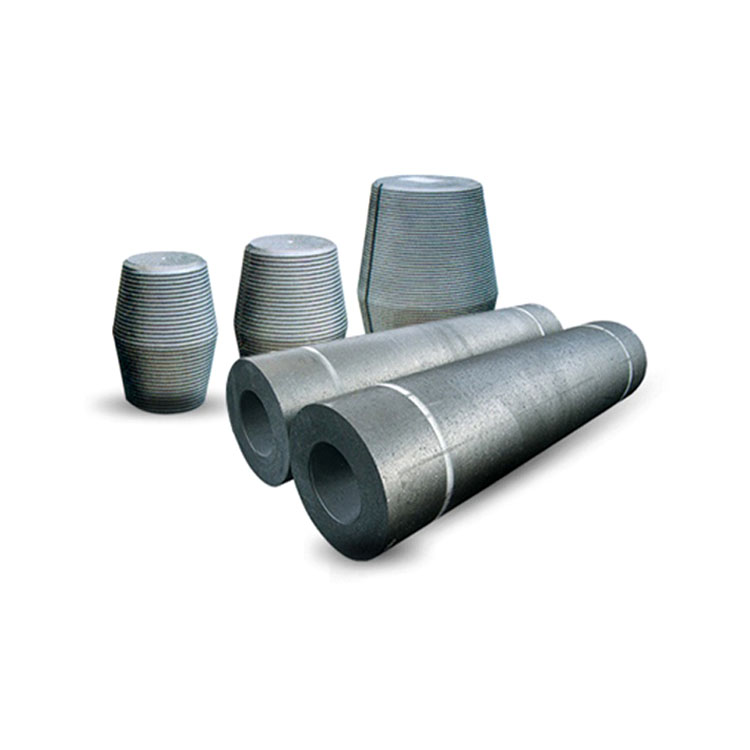

The precision cylindrical + threaded end design of extra - large diameter graphite electrodes is a key factor in improving connection strength and conductive consistency. The threaded end design ensures a tight connection between electrodes, which can effectively reduce energy loss during the current transfer process. Studies have shown that this design can reduce energy loss by up to 10% compared to non - threaded connections. The cylindrical shape also helps to maintain a stable electric field around the electrode, further enhancing the conductive performance.

Proper installation is essential for the performance of extra - large diameter graphite electrodes. First, ensure that the electrode holder is clean and free of debris. Then, carefully align the electrode with the holder and use a suitable tool to tighten the connection. The installation process should be carried out in a well - ventilated area to avoid the inhalation of graphite dust.

Regular daily inspections are necessary to ensure the normal operation of electrodes. Check the electrode surface for cracks, abrasions, and signs of overheating. Monitor the connection between electrodes for any signs of loosening or poor contact. In addition, pay attention to the temperature and current parameters during operation to detect any abnormal changes in a timely manner.

Determining the appropriate replacement time for electrodes is crucial to avoid production interruptions. Generally, when the electrode diameter is reduced to a certain level or when there are serious cracks or damage on the electrode surface, it is time to replace the electrode. For example, if the electrode diameter is reduced by more than 10% of the original diameter, replacement is recommended.

Common problems such as electrode breakage and poor connection can be solved through proper handling methods. If an electrode breaks, immediately stop the operation and remove the broken part. For poor connection problems, check the connection parts and clean or tighten them as needed.

Let's take a typical steel mill as an example. After using our extra - large diameter graphite electrodes, the unit energy consumption has decreased by 12%. At the same time, the electrode life has been extended by 20%. These data clearly show the significant benefits of using our products in improving production efficiency and reducing costs.

| Indicators | Before Using Our Product | After Using Our Product |

|---|---|---|

| Unit Energy Consumption (kWh/ton) | 400 | 352 |

| Electrode Life (Hours) | 100 | 120 |

Our extra - large diameter graphite electrodes not only improve production efficiency but also have significant environmental benefits. By reducing energy consumption, they can effectively reduce carbon emissions. In addition, the stable performance of these electrodes ensures high - yield and stable production, which is in line with the trend of green metallurgy. We have provided stable solutions for over 500 steel mills globally.

"The use of extra - large diameter graphite electrodes has brought us significant improvements in production efficiency and cost - reduction. It is a reliable choice for steel recycling." - A satisfied customer

Click to learn how to customize your exclusive electrode configuration solution!