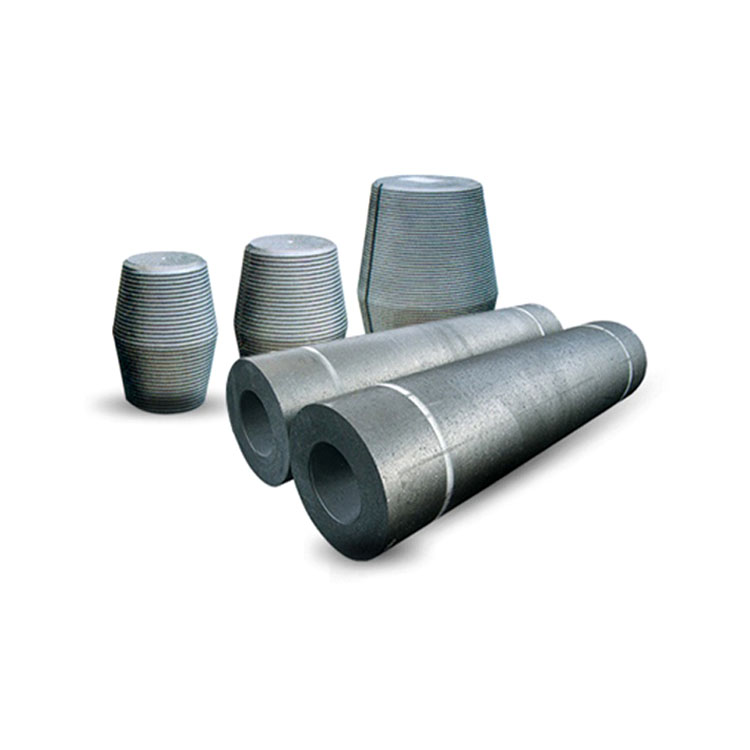

In the arc furnace steel recycling process, large-diameter (over 500mm) graphite electrodes play a pivotal role. Graphite electrodes are made of high - quality petroleum coke and needle coke, and are processed through strict procedures such as calcination, crushing, kneading, molding, roasting, impregnation, and graphitization. Their high conductivity and thermal stability are the keys to improving arc stability and furnace charge melting efficiency.

With a conductivity of up to 100 - 120 S/cm, large - diameter graphite electrodes can quickly conduct current, ensuring a stable arc. In contrast, ordinary electrodes may have a conductivity of only 80 - 90 S/cm. The thermal stability allows them to withstand high temperatures of up to 3000°C without significant deformation or damage, which is crucial for maintaining the long - term operation of the arc furnace. The unique structure of large - diameter graphite electrodes, with a dense and uniform internal structure, also contributes to their excellent performance.

When installing large - diameter graphite electrodes, it is necessary to ensure accurate alignment. The misalignment should be controlled within ±0.5mm. A proper installation angle, usually between 90°±1°, is also essential for stable arc generation. Before installation, the electrode surface should be cleaned to remove any impurities, which can improve the electrical contact.

During the operation, the current density should be strictly controlled. For large - diameter graphite electrodes, the recommended current density is 18 - 22 A/cm². Exceeding this range may lead to electrode overheating and damage. Regular inspection of the electrode consumption rate is also necessary. Generally, the consumption rate of large - diameter graphite electrodes in the arc furnace steel recycling process is about 1.5 - 2.5 kg/ton of steel.

When it comes to replacement, it is usually carried out when the remaining length of the electrode is less than 300mm. A well - planned replacement process can minimize production downtime. Here is a flowchart of the electrode maintenance cycle:

In a large - scale steel plant in the United States, after adopting large - diameter graphite electrodes in their arc furnace steel recycling process, they achieved a 15% increase in furnace charge melting efficiency. The arc stability was also significantly improved, reducing the occurrence of arc interruption by 20%. According to an expert in the field, "Large - diameter graphite electrodes are a game - changer in the steel recycling industry. Their high performance can bring substantial cost savings and productivity improvements."

Another case from a European steel mill shows that by following the correct installation and maintenance procedures, they extended the electrode life by 25%. This not only reduced the electrode procurement cost but also ensured the continuity of production.

In the context of the green smelting trend, large - diameter graphite electrodes have significant environmental benefits. Their high efficiency reduces energy consumption. On average, using large - diameter graphite electrodes can save about 10 - 15% of electricity consumption compared to traditional electrodes. This also means a reduction in carbon emissions, which is in line with the global environmental protection requirements.

From an economic perspective, although the initial investment in large - diameter graphite electrodes may be slightly higher, the long - term cost savings are obvious. The extended electrode life, improved production efficiency, and reduced energy consumption all contribute to cost optimization for steel enterprises.

Ready to revolutionize your steel recycling process with large - diameter graphite electrodes? Contact us to customize a solution tailored to your needs!