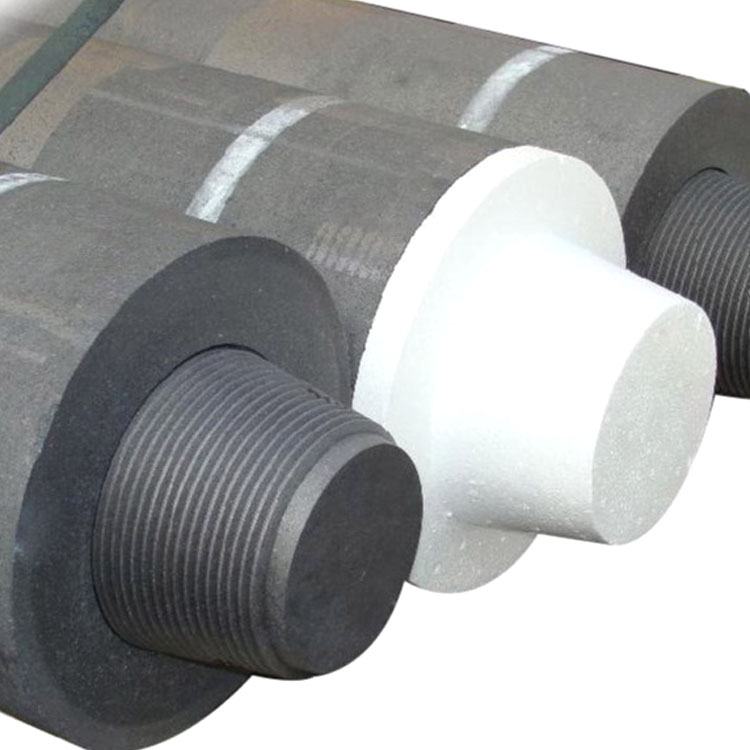

In the steel recycling process using electric arc furnaces, super - large diameter (over 500 mm) graphite electrodes play a crucial role. Understanding their operation, installation, and maintenance is essential for steel manufacturers to improve production efficiency and reduce costs.

Graphite electrodes are key components in electric arc furnaces. When an electric current passes through them, an arc is generated, which provides the high - temperature heat required to melt the scrap steel. The large diameter of these electrodes offers several advantages. For example, compared with smaller - diameter electrodes, super - large diameter electrodes can carry up to 30% more current, which significantly enhances arc stability. This stability is crucial as it reduces the likelihood of arc flicker, which can cause power fluctuations and damage to the furnace equipment. Moreover, the unique structure design of these electrodes improves the heat transfer efficiency, increasing the furnace charge melting rate by approximately 20%.

The installation of super - large diameter graphite electrodes requires strict adherence to industry standards. First, the electrode holder must be carefully inspected to ensure it is clean and in good condition. Any debris or damage can affect the electrical contact and lead to overheating. Then, the electrode is carefully lifted and aligned with the holder. The connection between the electrode and the holder should be tightened to a torque of about 500 - 600 Nm, as specified by the industry standard. This ensures a stable electrical connection and reduces the risk of electrode breakage during operation.

Regular maintenance is vital for extending the lifespan of graphite electrodes. During operation, the electrode consumption rate should be monitored. On average, a well - maintained super - large diameter electrode can last for about 100 - 120 furnace heats. When the electrode length is reduced to a certain level (usually about 1/3 of the original length), it needs to be replaced. The replacement process should be carried out quickly to minimize furnace downtime.

Many steel plants have successfully applied super - large diameter graphite electrodes in their production. For example, a steel mill in Europe reported a 15% reduction in energy consumption and a 12% increase in production capacity after switching to these electrodes. These results not only demonstrate the environmental and energy - saving benefits but also highlight the potential for cost - reduction and efficiency improvement in the steel industry.

Super - large diameter graphite electrodes offer significant advantages in electric arc furnace steel recycling. By understanding their working principles, following proper installation and maintenance procedures, and learning from real - world case studies, steel manufacturers can enhance their production efficiency, reduce costs, and contribute to a more sustainable steel - making process.

If you want to learn more about how to optimize your steel recycling process with super - large diameter graphite electrodes, click here to explore our detailed solutions and boost your production efficiency!