In continuous casting operations, inefficient ladle heating can disrupt production rhythms and increase energy costs. Based on real-world data from a mid-sized steel plant in Southeast Asia, we demonstrate how adjusting insulation design and baking parameters can reduce heating time by up to 27%—without compromising temperature uniformity.

Traditionally, many plants rely on single-layer refractory blankets that fail to retain heat efficiently during the initial phase of heating. Our field tests show that without optimized insulation, it takes an average of 145 minutes to reach 1,000°C from ambient temperature—a delay that impacts melt scheduling and increases fuel consumption.

| Parameter | Before Optimization | After Optimization |

|---|---|---|

| Heating Time (to 1,000°C) | 145 min | 105 min |

| Temperature Uniformity (±°C) | ±120°C | ±45°C |

| Energy Consumption (kWh/ton) | 185 kWh | 152 kWh |

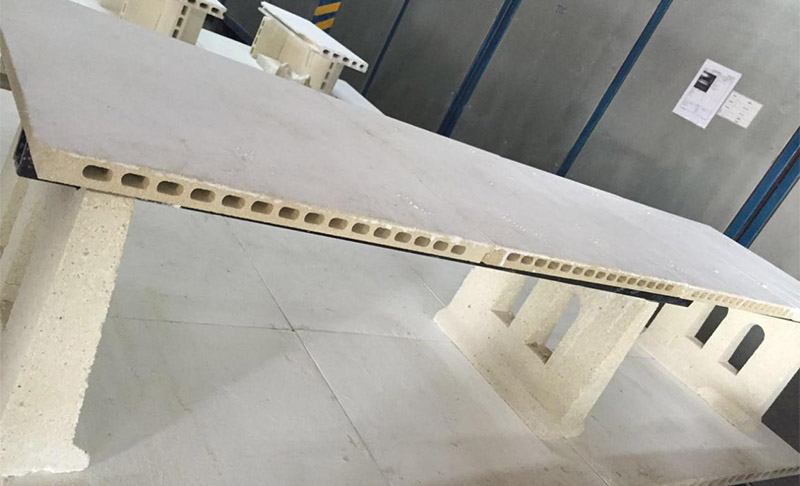

The key lies in structured thermal management. By implementing a three-layer system—outer ceramic fiber blanket, middle high-density alumina board, and inner low-conductivity vermiculite layer—we achieved significant improvements:

This configuration reduced thermal gradient across the ladle wall by over 60%, ensuring faster and more even heating—critical for maintaining consistent steel quality in downstream processes.

Based on our pilot program, here are actionable steps for operators:

These small changes translate into big gains—not just in efficiency but also in safety and process stability.

Pro Tip: If you're evaluating new insulating materials, consider conducting a side-by-side test with your current setup—one week of comparative trials often reveals unexpected savings.

For engineers and plant managers looking to enhance ladle performance, exploring advanced refractory solutions like Sunrise’s high-performance vermiculite insulation boards offers a proven path forward.

Explore Sunrise's Advanced Refractory Solutions