Maintaining graphite electrodes in Electric Arc Furnaces (EAFs) is a critical aspect of ensuring continuous steel production and enhancing energy efficiency. This guide provides in - depth insights into the practical aspects of EAF graphite electrode maintenance, covering daily inspections, common fault prevention, and the importance of proper electrode selection.

Regular daily inspections are the first line of defense in preventing electrode - related issues. Here are some key points to focus on:

Understanding common faults and their causes is crucial for effective prevention. Here are some typical issues and how to avoid them:

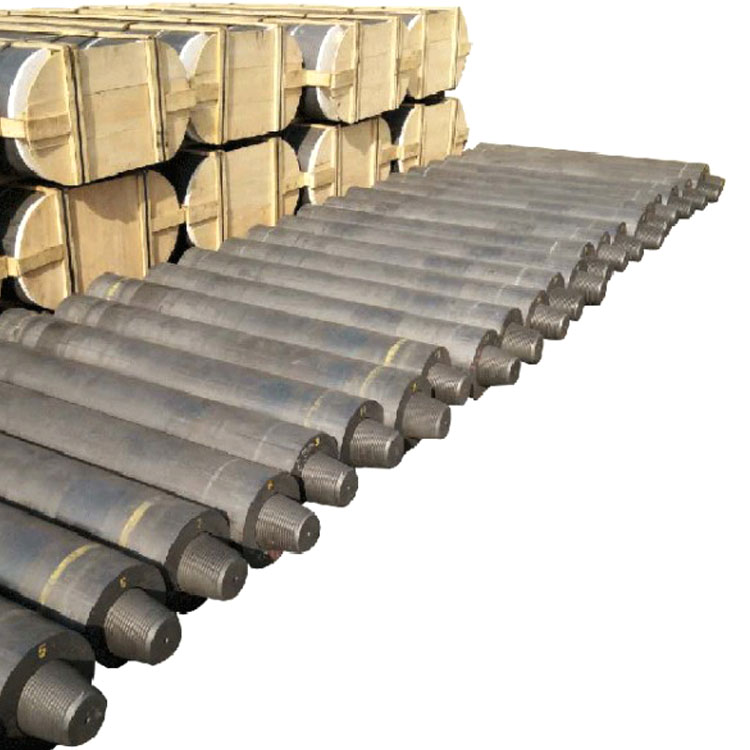

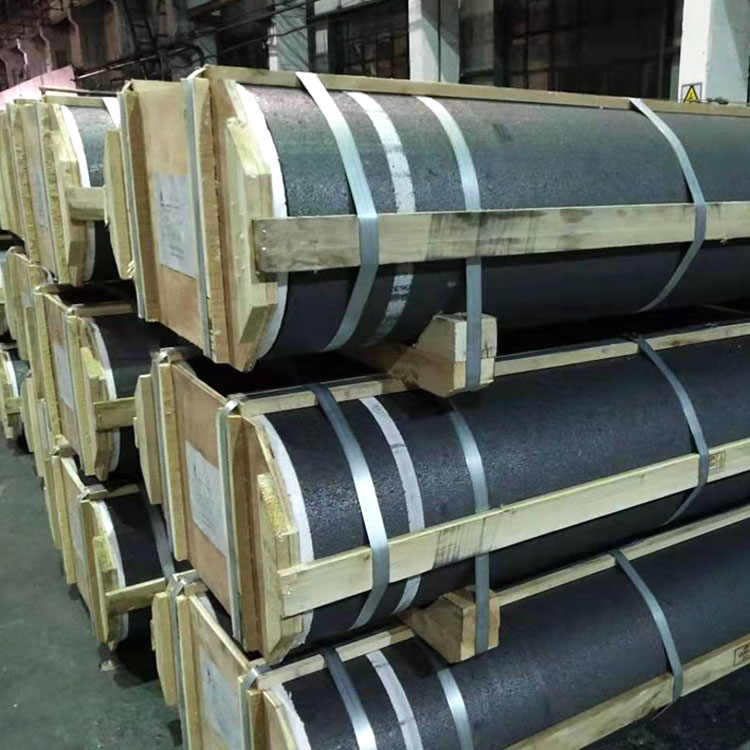

Electrode breakage can occur due to various reasons, such as mechanical stress, thermal shock, or poor electrode quality. To prevent breakage, ensure proper handling during installation, avoid sudden temperature changes, and select high - quality electrodes. For example, using electrodes made from high - grade needle coke can improve their mechanical strength and resistance to breakage.

Overheating and ablation are often caused by high current density, improper electrode selection, or poor electrical contact. To prevent these issues, match the electrode diameter and current density to the furnace requirements. Regularly clean the electrode surface and joints to ensure good electrical conductivity.

Selecting the right electrode is as important as proper maintenance. Consider the following factors:

There are many misconceptions in the industry regarding electrode selection. For example, some believe that higher - power electrodes are always better, regardless of the furnace requirements. In fact, improper selection can lead to increased energy consumption and reduced electrode lifespan.

Here is an anonymized customer success story to illustrate the benefits of proper electrode maintenance and selection:

A steel plant was experiencing frequent non - planned furnace shutdowns due to electrode failures. After consulting with our experts, they optimized their electrode selection based on furnace type and operating conditions. As a result, they were able to reduce electrode breakage by 30% and achieve a 15% energy savings.

To help you quickly assess the electrode status, we provide a simple evaluation table. You can download it or use it online. This table will assist you in identifying potential problems and taking timely actions.

| Inspection Item | Acceptable Status | Action Required |

|---|---|---|

| Surface Cracks | No visible cracks | Replace the electrode if cracks are detected |

| Joint Looseness | Tightly connected | Tighten the joints |

| Temperature | Within normal range | Check electrical contact and current density if abnormal |

Is your electrode at risk? Click here to check now and optimize your EAF graphite electrode maintenance!