In the global steel industry's green and low-carbon transformation, the demand for high-performance electrodes in large-capacity electric arc furnaces (EAFs) is increasing. This article delves into the key manufacturing process optimization experiences of ultra-high power graphite electrodes in the EAF steel recycling process.

The combination of high-quality needle coke raw materials and precision machining technology plays a crucial role in enhancing the conductivity, thermal stability, and connection reliability of graphite electrodes. For example, high-quality needle coke can provide a more ordered molecular structure, which is beneficial to the transfer of electrons, thereby improving the conductivity of the electrode. According to industry reports, electrodes made from high-quality needle coke can increase conductivity by about 10% - 15% compared with ordinary electrodes.

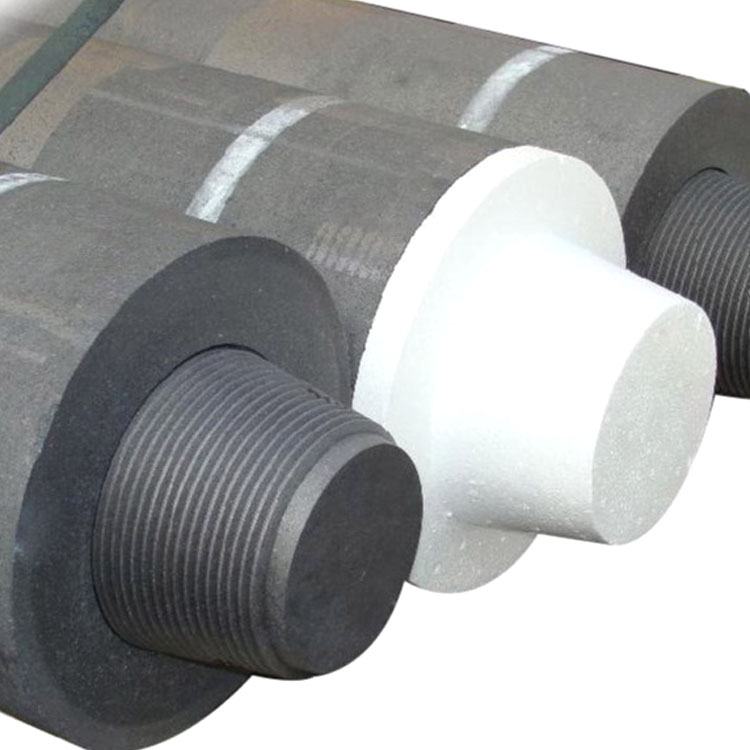

The entire process of graphite electrode manufacturing starts from raw material selection. The choice of needle coke with appropriate properties is the first step to ensure the quality of the final product. Then, through a series of processes such as mixing, molding, roasting, and graphitization, the raw materials are gradually transformed into graphite electrodes with specific performance.

In the machining process, precision machining technology is used to ensure the dimensional accuracy and surface quality of the electrodes. This not only affects the connection reliability between electrodes but also has an impact on the overall performance of the electrodes in the arc furnace. For instance, a precise connection can reduce the contact resistance, which is conducive to energy - saving and improving the service life of the electrodes.

By introducing successful cases of international steel enterprises, we can see that the use of high - performance ultra - high power graphite electrodes can bring significant benefits to enterprises. For example, an international steel company has achieved an energy - saving rate of about 15% in its arc furnace after replacing traditional electrodes with high - performance graphite electrodes, and at the same time, production efficiency has been increased by about 10%.

Combined with energy - efficiency standards and environmental protection policies, the market for ultra - high power graphite electrodes is growing. The demand for high - performance electrodes in large - capacity arc furnaces is increasing due to the requirements of energy - saving and environmental protection. The market growth logic is clear: enterprises need to meet energy - efficiency standards and environmental protection policies while improving production efficiency.

Our ultra - high power graphite electrodes have obvious product differentiation advantages. The combination of high - quality raw materials and advanced manufacturing technology makes our electrodes have better conductivity, thermal stability, and connection reliability. This not only helps enterprises achieve energy - saving and consumption - reduction goals but also improves production efficiency.

For customers, choosing our products means choosing more stable furnace conditions and lower operating costs. Let every electrode become a key fulcrum for your energy - saving and efficiency - increasing. We can provide customers with detailed product parameters and technical support services to help them make more informed purchasing decisions.

In addition to the manufacturing process, proper maintenance of graphite electrodes is also crucial. Regular inspection of electrode connections, surface conditions, and proper storage can extend the service life of electrodes. This article also shares some practical maintenance points to help users better use and maintain electrodes.

If you want to further understand product parameters and technical support services, please click the button below. We are committed to providing you with the most professional and detailed information to help you make the best choice for your enterprise.

Click to Learn More about Ultra - High Power Graphite Electrodes