Needle coke, as the core raw material for ultra - high power graphite electrodes, plays a crucial role in the performance of electric arc furnaces (EAFs). Its unique microstructural advantages have a decisive impact on the conductivity and thermal shock resistance of electrodes. The highly oriented needle - like structure of needle coke allows for efficient electron flow, significantly enhancing the conductivity of the electrode. In fact, electrodes made from high - quality needle coke can achieve a conductivity improvement of up to 20% compared to those made from ordinary raw materials.

Thermal shock resistance is another key factor in electrode performance. The needle - like structure of needle coke can effectively absorb and disperse thermal stress, reducing the risk of electrode cracking during the high - temperature operation of the EAF. This ensures the stability of the electrode during long - term use and reduces the frequency of electrode replacement, which can save up to 15% in maintenance costs for steel plants.

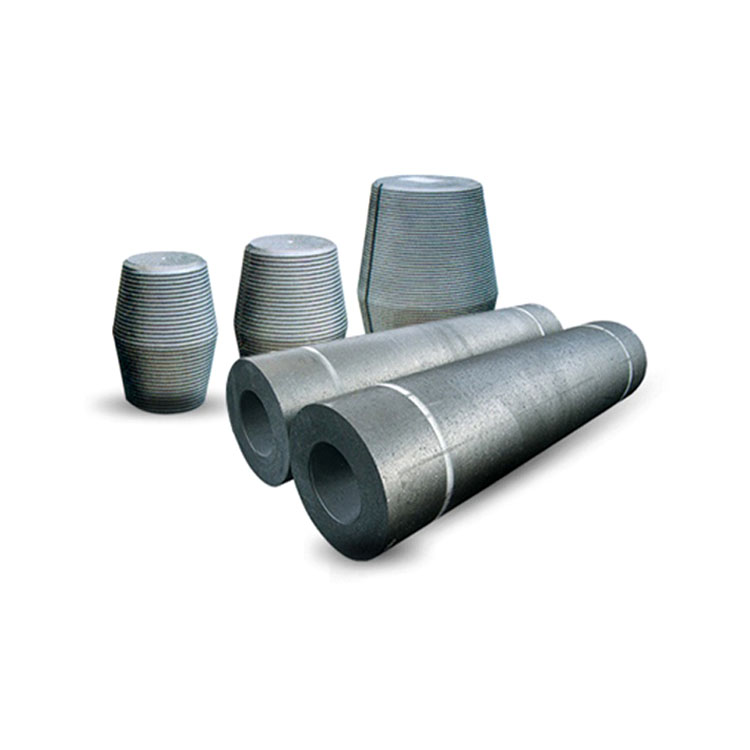

In modern EAF processes, the trend towards using large - diameter electrodes (over 500mm) is becoming increasingly evident. Large - diameter electrodes can provide higher power input, which is beneficial for increasing the melting rate of scrap steel and improving the production efficiency of steel plants. For example, a steel plant using 600mm diameter electrodes can increase its melting rate by approximately 18% compared to one using 500mm diameter electrodes.

However, the application of large - diameter electrodes also brings some challenges. One of the main challenges is the increased risk of electrode breakage due to the higher mechanical stress during operation. In addition, the manufacturing process of large - diameter electrodes requires more precise control to ensure uniform quality. The failure rate of large - diameter electrodes can be up to 5% higher than that of small - diameter electrodes if not properly manufactured and used.

The reliability of electrode connection is crucial for the stable operation of EAFs. Machining precision and end thread design have a significant impact on electrode connection reliability. High - precision machining can ensure a perfect fit between the electrode and the connector, reducing the contact resistance and improving the current conduction efficiency. Even a small deviation in machining accuracy can lead to a 10% increase in contact resistance, which may cause local overheating and damage to the electrode.

The design of the end thread also plays an important role. A well - designed thread can evenly distribute the stress during electrode connection, reducing the risk of thread damage and electrode disconnection. For example, a new - type thread design can reduce the stress concentration by up to 30%, significantly improving the connection reliability.

Electrode failure can have serious consequences for steel plants. Let's take a look at a real - world scenario. A medium - sized steel plant experienced an electrode failure during the melting process. The sudden breakage of the electrode led to a shutdown of the EAF for 8 hours. During this period, the plant not only lost the production capacity but also incurred additional costs for equipment maintenance and electrode replacement. The total loss was estimated to be approximately $50,000.

A certain enterprise replaced its old electrodes with high - performance electrodes made from high - quality needle coke. Through a series of optimizations, including electrode selection and process adjustment, the enterprise achieved an energy - saving effect of 15%. The specific path included improving the conductivity of the electrode, reducing the heat loss during the melting process, and optimizing the operation parameters of the EAF. This not only reduced the energy consumption cost but also contributed to the green and efficient production of the enterprise.

To ensure the stable operation of EAFs and the performance of electrodes, we provide a practical inspection checklist and electrode condition assessment table. The inspection checklist includes items such as electrode appearance inspection, connection tightness check, and temperature monitoring. The electrode condition assessment table can help steel engineers and procurement decision - makers quickly evaluate the condition of electrodes and make timely replacement decisions.

| Inspection Item | Inspection Method | Acceptance Criteria |

|---|---|---|

| Electrode Appearance | Visual Inspection | No cracks, pits, or significant wear |

| Connection Tightness | Torque Wrench Check | Torque within specified range |

| Temperature Monitoring | Infrared Thermometer | Temperature within normal operating range |

Complex concepts such as current conduction paths and joint stress distribution can be difficult to understand. To enhance the understanding efficiency, we recommend using information charts, such as flowcharts and contrast diagrams. These charts can visually present the complex relationships and processes, making it easier for steel engineers and procurement decision - makers to grasp the key points.

Are you looking for solutions to optimize your EAF electrode performance and achieve green and efficient production? Click here to learn more about our high - quality needle coke graphite electrodes and professional services.