If you are struggling with slow ladle warm-up times or inconsistent temperature distribution during steel processing, you're not alone. Many steelmakers face these challenges, which can disrupt your production rhythm and impact molten steel quality. The core issue often lies in the ladle insulation design, where an excessively thick refractory lining absorbs too much heat and impedes efficient heat transfer.

When the refractory lining inside your ladle is too thick or poorly structured, heat is trapped within the insulation. This causes the ladle shell to remain cooler and extend your preheating cycle. Over time, this inefficiency can lead to uneven temperature zones in the ladle, increasing thermal stress and risking molten steel quality degradation.

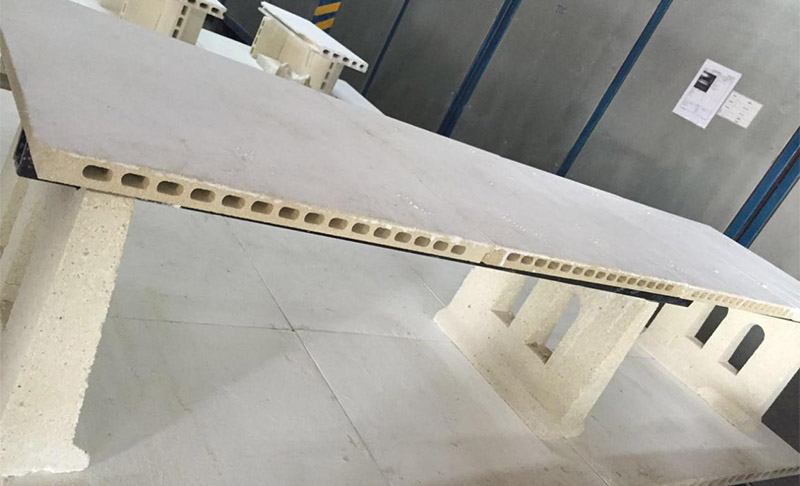

A well-designed ladle insulation follows a three-layer system, where the third layer plays a crucial role. Replacing the conventional bulky refractory material in this outer layer with lightweight, high-strength insulating boards can significantly improve heat retention without compromising mechanical integrity.

One standout solution is the alumina-based vermiculite Sunrise ladle insulation board. This advanced refractory material combines high-temperature resistance with low thermal conductivity and chemical corrosion durability. Its unique composition facilitates uniform heat distribution across the ladle lining, effectively reducing localized hot spots and thermal gradients.

By switching to these boards, you can reduce the insulation thickness by 10 to 18 millimeters, lowering outer shell temperatures by up to 50°C. This not only shortens the preheating duration but also enhances overall operational efficiency.

| Parameter | Before Optimization | After Optimization | Improvement |

|---|---|---|---|

| Insulation Thickness (mm) | 45-55 | 35-40 | 18% avg. reduction |

| Maximum Ladle Shell Temperature (°C) | ~230 | ~180 | ~50°C decrease |

| Preheating Time (min) | 120-130 | 90-95 | ~30% reduction |

| Energy Consumption (KWh) | 1000 | 850 | 15% saving |

To fully leverage these material upgrades, you should fine-tune your bake curve and time allocation. Gradually ramping temperatures and allowing controlled dwell periods optimize heat penetration and minimize thermal stress. Matching these process parameters with insulation enhancements pay dividends in reducing overall downtime and maintenance costs.

A leading steel producer recently implemented Sunrise alumina vermiculite boards as an outer insulation layer and reported a 30% boost in overall ladle baking efficiency alongside a 15% reduction in energy costs. Such performance gains exemplify the tangible benefits achievable when material innovation meets process optimization.

Unlock your ladle’s full potential - Discover how Sunrise High-Performance Refractory Materials Can Transform Your Production