High-power graphite electrodes are crucial components in electric arc furnaces for steelmaking. However, they often encounter several common failure phenomena during continuous operation. These include end spalling, sidewall cracking, and joint loosening. End spalling can lead to a significant loss of electrode material, while sidewall cracks may compromise the structural integrity of the electrode, and joint loosening can cause poor electrical conductivity and even safety hazards.

During the operation of the electric arc furnace, the high-power graphite electrode is subjected to extremely high temperatures. The rapid heating and cooling process generates thermal stress, which, when concentrated at certain points, can cause the electrode to crack or spall. For example, in some cases, the thermal stress can reach up to 80 MPa, which is far beyond the allowable stress of the graphite electrode material.

In the high-temperature and oxygen-rich environment of the electric arc furnace, the graphite electrode is prone to oxidation and corrosion. The oxidation rate can be as high as 0.5 - 1 mm per hour under certain conditions. This not only reduces the diameter of the electrode but also weakens its mechanical properties, increasing the risk of failure.

The electrode is also subject to mechanical impact during the operation, such as the impact caused by the movement of the furnace charge and the vibration of the furnace. These mechanical impacts can cause micro - cracks in the electrode, which gradually expand over time and lead to severe failures.

If the heating rate of the graphite electrode is too fast, the thermal stress generated inside the electrode will be too large, resulting in cracking. According to industry experience, a heating rate exceeding 50°C per hour can significantly increase the risk of electrode failure.

Uneven clamping force on the electrode can cause local stress concentration, leading to sidewall cracks and joint loosening. For example, if the clamping force difference between different parts of the electrode exceeds 20%, it can have a negative impact on the electrode's performance.

Inadequate cooling of the electrode can lead to overheating, which accelerates oxidation and corrosion. A proper cooling system can reduce the electrode temperature by 100 - 200°C, effectively improving its service life.

By adjusting the installation angle of the electrode, the distribution of thermal stress and mechanical impact can be optimized. According to international standards and practical experience, an appropriate installation angle can reduce the risk of end spalling by about 30%.

Upgrading the cooling system can effectively improve the cooling efficiency of the electrode. For example, using a more advanced cooling medium and optimizing the cooling channel design can increase the cooling rate by 20 - 30%, thereby reducing the oxidation and corrosion rate.

Online monitoring technology can continuously monitor the temperature, stress, and other parameters of the electrode in real - time. By analyzing these data, potential failure risks can be detected in advance, and preventive measures can be taken. This can reduce unplanned downtime by about 40%.

Based on the above analysis and improvement measures, establishing an electrode health status evaluation system is crucial. This system can comprehensively evaluate the health status of the electrode through multi - parameter monitoring and data analysis. For example, in a certain steelmaking plant, after implementing the electrode health status evaluation system, the average service life of the electrode has been increased by 25%, and the production cost has been reduced by 15%.

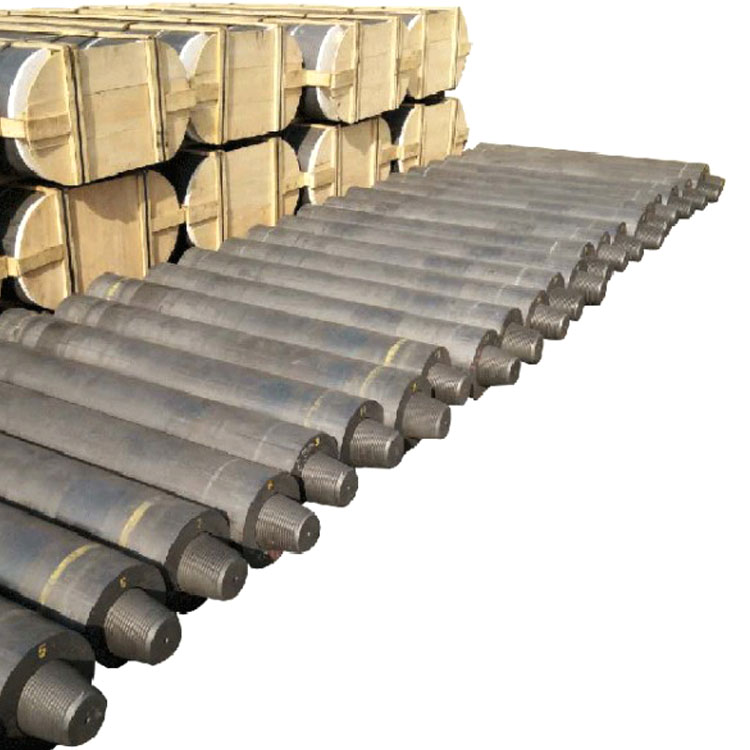

In conclusion, our company has in - depth knowledge and rich experience in the field of high - power graphite electrodes. We can provide you with customized solutions based on your specific needs. As a long - term reliable partner, we are committed to helping you improve the stability of your arc furnace production, extend the service life of your electrodes, and reduce production costs. If you want to know more about our high - power graphite electrode products and services, please click here.