High-Power Graphite Electrode Selection Guide: From Process Analysis to Precise Matching in Electric Arc Furnace Steelmaking

This article provides a comprehensive, step-by-step guide to selecting high-power graphite electrodes for different steel grades in electric arc furnace (EAF) operations. It analyzes key performance parameters—thermal conductivity, oxidation resistance, thermal shock resistance, and resistivity—and correlates them with real-world process conditions such as melting temperature, slag composition, and oxygen blowing intensity. Through practical case studies and on-site testing methods, it highlights risks of improper electrode use and offers actionable solutions to prevent equipment damage and production incidents. Designed for technical decision-makers in steel manufacturing, this guide supports smarter procurement and application strategies with clear visuals and data-driven insights.

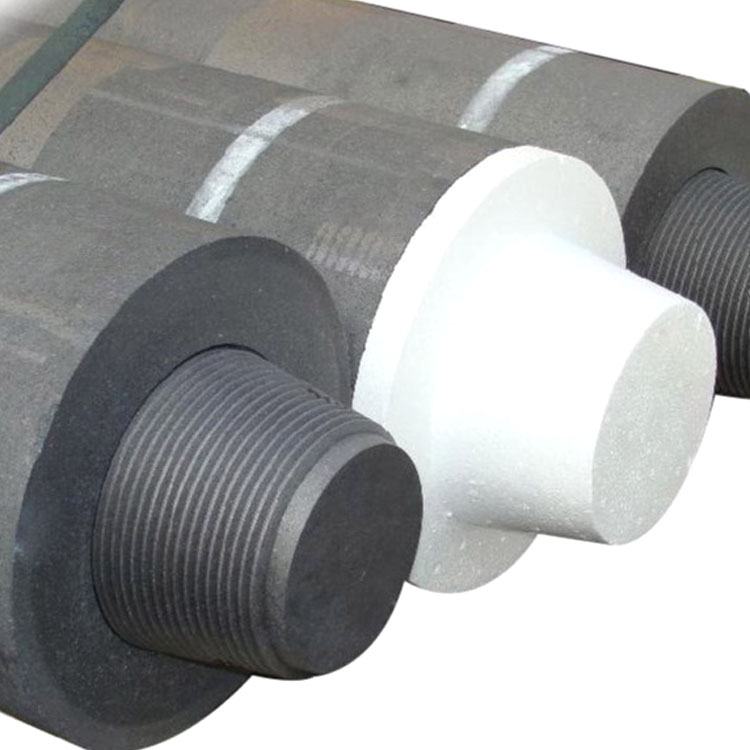

Mastering High-Power Graphite Electrode Selection for Arc Furnace Steelmaking

Choosing the right high-power graphite electrode isn’t just about performance—it’s about avoiding costly mistakes in steel production. Whether you're melting stainless steel or alloyed grades, selecting an electrode that matches your furnace conditions can prevent premature failure, reduce downtime, and improve energy efficiency.

Key Performance Parameters You Can’t Ignore

Industrial buyers often overlook these four critical parameters when sourcing electrodes:

- Thermal Conductivity (W/m·K): Higher values (typically 120–180 W/m·K) mean better heat dissipation—crucial for reducing thermal stress during rapid heating cycles.

- Oxidation Resistance: At temperatures above 800°C, carbon oxidation accelerates. Electrodes with boron nitride coatings or impregnated pitch show up to 40% longer life in oxidizing environments.

- Thermal Shock Resistance: Measured by the ability to withstand sudden temperature changes without cracking. For electric arc furnaces (EAFs), this should exceed 300°C/min in lab tests.

- Electrical Resistivity (μΩ·cm): Lower resistivity = less power loss. Premium-grade electrodes range from 12–18 μΩ·cm, while standard ones may exceed 25 μΩ·cm.

Real-World Application: Why One Steel Mill Lost $120K in a Single Week

A mid-sized EAF plant in Southeast Asia used general-purpose graphite electrodes for producing 304 stainless steel—a decision that led to frequent electrode breakage due to poor thermal shock resistance. After analyzing their process data (melting temp: 1650°C, slag basicity: 1.8, oxygen blowing intensity: 120 m³/h), we found the electrodes were operating beyond their design limits. Switching to a high-power grade with enhanced SiC additives reduced electrode consumption by 37% and eliminated unplanned shutdowns.

How to Build Your Own Selection Workflow

Here’s a practical framework used by top-tier steel producers:

- Define your primary steel grade (e.g., carbon steel vs. alloy steel).

- Record average melting temperature (°C) and duration per batch.

- Assess slag composition (basicity index, MgO content).

- Measure oxygen injection rate (m³/h) and frequency of tapping.

- Select electrodes with matching specs—use our custom electrode calculator for instant recommendations.

Common Mistakes & How to Avoid Them

Many mills still rely on outdated practices like buying by price alone or using the same electrode across all products. This leads to:

- Increased electrode consumption (up to 25% more than optimal)

- Higher risk of arc instability and refractory damage

- Reduced scrap-to-steel yield due to contamination from degraded electrodes

Pro tip: Always run a pilot test with new electrode batches before full-scale adoption. A simple 3-batch trial under real-world conditions can save thousands in long-term losses.

Need help choosing the perfect electrode for your specific application? Our technical team offers free consultation and custom formulation support—no obligation, just expert guidance tailored to your process.

Get Your Customized Electrode Recommendation Today