How to Evaluate High-Power Graphite Electrodes for Electric Arc Furnace Applications by Steel Grade

05 01,2026

Tutorial Guide

This article provides a technical guide for steelmakers to assess the suitability of high-power graphite electrodes in electric arc furnaces (EAF), focusing on how different steel types—such as stainless steel and alloy steel—affect electrode performance. It analyzes key parameters including thermal conductivity, oxidation resistance, thermal shock resistance, and electrical resistivity, while integrating real-world operational factors like melting temperature, slag composition, and oxygen blowing intensity. A practical selection flowchart and field testing methods are included to support informed decision-making. Real-world misuse cases highlight potential production risks and economic losses, offering critical lessons for process optimization. Designed for EAF professionals seeking precise electrode matching across steel grades, this guide enhances both safety and efficiency through data-driven insights and actionable recommendations.

How to Choose the Right High-Power Graphite Electrode for Your Arc Furnace

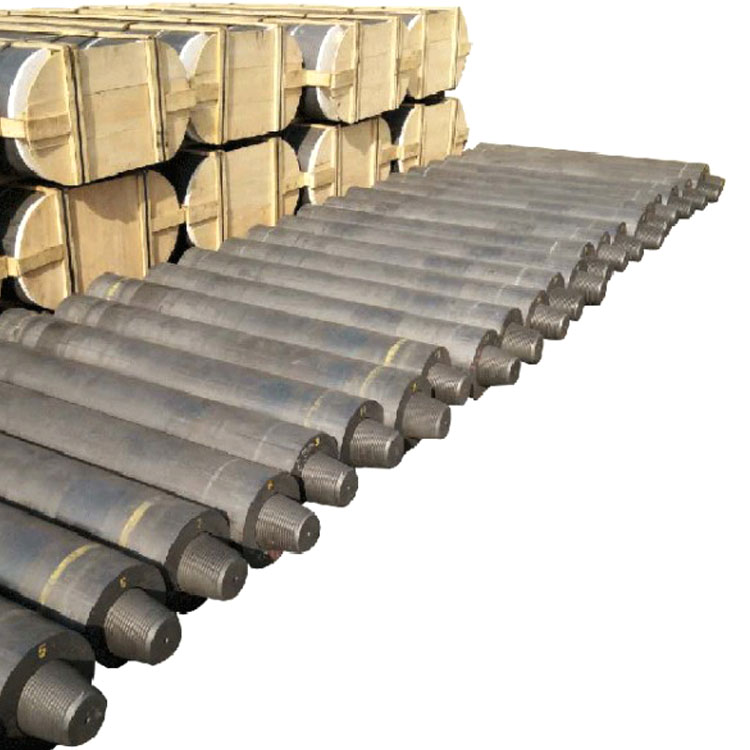

Selecting the correct high-power graphite electrode isn’t just about performance—it’s a strategic decision that impacts efficiency, safety, and cost. In electric arc furnace (EAF) steelmaking, especially when processing stainless steel or alloy steels, using the wrong electrode can lead to unexpected downtime, increased scrap rates, and even equipment damage.

Key Parameters That Matter Most

The right electrode must match both the chemical and thermal demands of your specific steel grade. Here are the four core parameters:

- Thermal Conductivity: For high-temperature melts like stainless steel (>1600°C), electrodes with ≥120 W/m·K are essential to prevent hot spots and uneven wear.

- Thermal Shock Resistance: A good electrode should withstand rapid temperature changes—typically from room temp to over 2500°C in minutes. Look for materials with ≤0.3% linear expansion after 5 cycles.

- Oxidation Resistance: At 1500–1700°C, oxidation becomes critical. Electrodes with boron nitride coatings or silicon carbide additives reduce consumption by up to 25%.

- Electrical Resistivity: Lower resistivity (≤12 μΩ·m) means less energy loss per kilowatt-hour—directly improving operating economics.

Real-World Impact: When Misselection Costs More Than You Think

A mid-sized EAF plant in Turkey once used standard power electrodes for producing 316L stainless steel. Within two months, they experienced:

- 30% faster electrode consumption vs. expected norms

- Unplanned shutdowns due to electrode breakage during tapping

- Increased maintenance costs (~$45,000/month)

This case highlights why generic recommendations fail—and how tailored solutions matter.

Field Testing Tips for On-Site Validation

Before full-scale adoption, test electrodes under real conditions:

- Run a 48-hour trial batch with controlled variables (same charge mix, oxygen intensity, melting time).

- Monitor electrode consumption rate per ton of steel—ideal range: 0.8–1.2 kg/ton for premium grades.

- Check surface condition post-melt using infrared thermography to detect hotspots.

These simple checks help avoid costly mistakes and ensure long-term reliability—even in harsh environments like those found in Middle Eastern and Southeast Asian plants.

Why Custom Solutions Beat One-Size-Fits-All

Every EAF has unique challenges—from slag chemistry to operator behavior. That’s why we offer custom electrode formulations based on:

- Steel composition (Cr, Ni, Mo content)

- Furnace load profile (continuous vs. batch melting)

- Local climate impact (humidity affects electrode handling)

Our technical team works directly with your engineers—not just as suppliers, but as partners in process optimization.