High-Power Graphite Electrode Misapplication Analysis Based on Field Data and Prevention Strategies

05 02,2026

Customer Cases

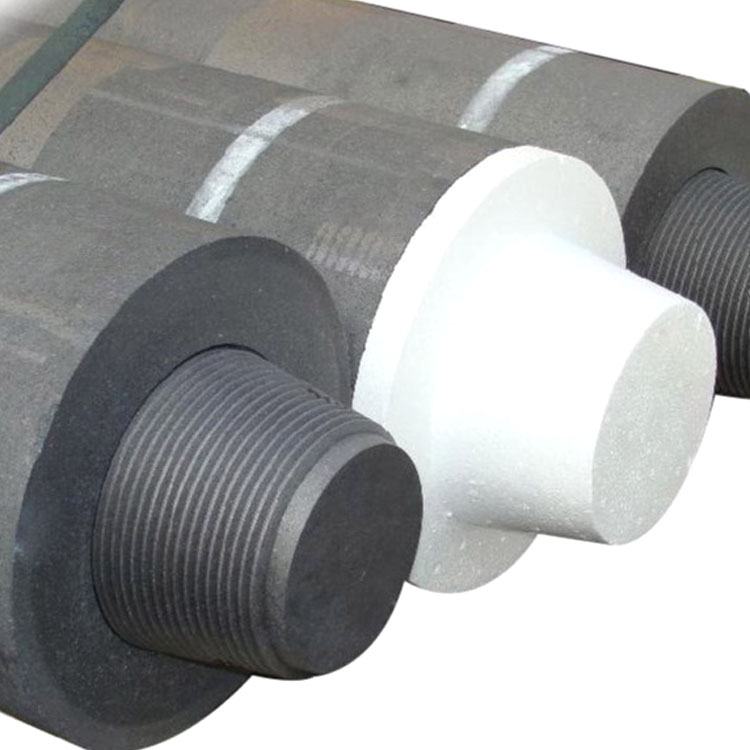

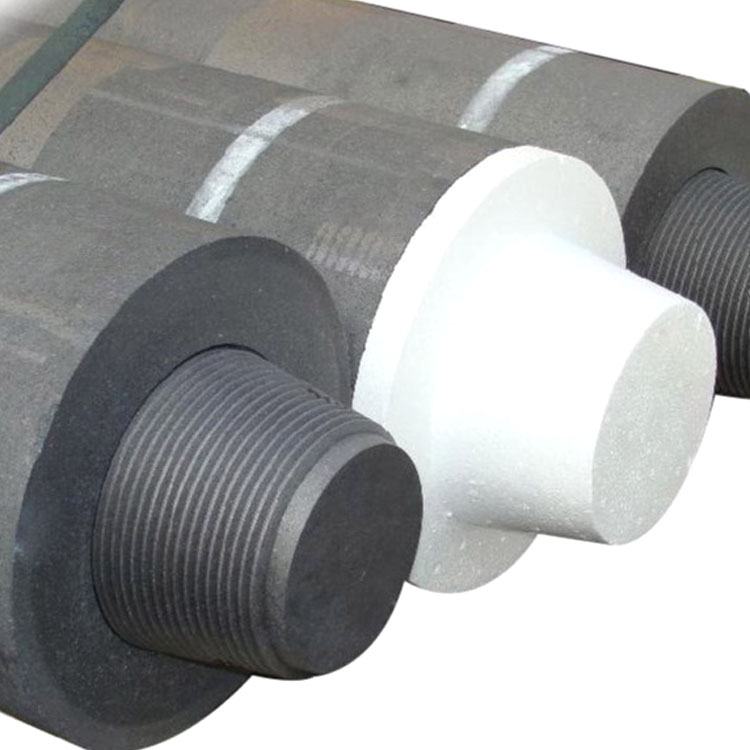

This article addresses common challenges steel mills face in selecting high-power graphite electrodes for electric arc furnace operations. Leveraging real-world field data, it thoroughly analyzes misuse cases—such as the premature consumption and power failures caused by using conventional power electrodes in stainless steel melting. Key parameters including thermal conductivity, oxidation resistance, thermal shock resistance, and electrical resistivity are systematically examined to demonstrate their suitability for different steel types like alloy steel, high-carbon steel, and stainless steel. Practical selection flowcharts and on-site testing methods are provided to guide technical teams in making data-driven electrode matching decisions, minimizing risks, and enhancing production efficiency and equipment safety.

Understanding High-Power Graphite Electrode Misuse in Electric Arc Furnace Steelmaking

As a steel plant’s technical professional or procurement lead, you may have encountered unexpected electrode failures, rapid wear, or costly downtime linked to graphite electrode mismatches. Misuse of graphite electrodes—especially substituting high-power electrodes with conventional types in demanding applications such as stainless steel melting—can severely impact production efficiency and equipment lifespan. This article dives deep into real-world data-backed misuse cases and explains how critical technical parameters govern optimal electrode selection. Our aim is to empower you with practical insights and tools to enhance decision-making and operational safety.

Common Pain Points in Electrode Selection: The Hidden Costs

You may have experienced unscheduled furnace stoppages, sudden power cuts, and unexpected electrode consumption that spike your maintenance costs. These issues often stem from ignoring the unique electrothermal characteristics each steel grade demands. For instance, using a conventional graphite electrode in a stainless steel melt leads to:

- Excessive electrode oxidation accelerating consumption rates by up to 30%

- Electrode breakage triggered by poor thermal shock resistance

- Electrical inefficiency increasing power input requirements

Your plant might be paying the price for electrode misuse without realizing the root cause.

Key Technical Parameters: What Truly Matters?

Selecting the correct electrode demands in-depth understanding of four pivotal parameters:

- Thermal Conductivity: Determines heat dissipation speed to control electrode temperature peaks.

- Oxidation Resistance: Critical for electrodes exposed to aggressive slag and oxygen-rich atmospheres, especially in stainless steel melting.

- Thermal Shock Resistance: Guards against cracking due to rapid temperature fluctuations during furnace operation.

- Electrical Resistivity: Influences power consumption efficiency and arc stability.

For example, high-power electrodes suited to alloy and stainless steels typically feature 15-25% higher oxidation resistance and 10-15% better thermal shock resistance compared to conventional electrodes, ensuring longer service life and operational stability.

Operational Factors That Dictate Electrode Choice

Beyond material properties, specific furnace conditions shape electrode requirements. Consider:

- Melting Temperature: Higher melts (>1600°C) demand electrodes with exceptional thermal stability.

- Slag Composition: Aggressive slags with high alkali oxides require electrodes with enhanced chemical resistance.

- Oxygen Blowing Intensity: Intense oxygen supply increases electrode oxidation risk, necessitating superior protective grades.

Interactive Check: Has your facility evaluated these parameters against actual operating conditions recently? If not, misapplication risks remain high.

Real-World Case Study: The Cost of Using Conventional Electrodes in Stainless Steel Melting

A mid-size steel mill reported recurrent electrode failures during stainless steel production. Field data revealed that conventional electrodes were being used instead of recommended high-power types. Consequences included:

- Electrode consumption 40% above benchmark, leading to increased raw material costs

- Unexpected power interruptions–over 15 events in six months–due to electrode breakage

- Reduced furnace availability, cutting overall productivity by 8%

Post-installation of correctly matched high-power electrodes designed for stainless steel melting:

- Electrode life extended by 30%

- Zero power interruption incidents in the following quarter

- Operational efficiency and energy utilization improved measurably

Step-by-Step Electrode Selection & Validation Workflow

To avoid costly errors, implement a data-driven electrode selection process:

- Assess Steel Grade & Melting Parameters: Analyze chemical and thermal requirements.

- Evaluate Electrode Key Indices: Confirm thermal conductivity, oxidation & shock resistance, resistivity match.

- Check Furnace Operating Conditions: Temperature, slag composition, oxygen levels.

- Select Electrode Type: Prefer high-power or ultra-high-power grades where applicable.

- Pilot Testing & Field Verification: Measure electrode consumption, breakage, and electrical parameters in situ.

- Feedback Loop: Document performance; refine selection criteria continuously.

Preventive Measures: Building Your Standardized Electrode Matching System

Proactively reduce risks by adopting:

- Strict adherence to selection protocols based on steel grades and operating factors

- Regular training for technical and purchasing teams on electrode specifications

- Use of comprehensive onsite testing methods – such as electrical resistance and oxidation rate measurements

- Collaborative data sharing with electrode suppliers to enhance product customization and performance

Your Turn: Does your plant have a standardized method for electrode selection and verification? If inconsistent practices persist, operational risks and costs remain elevated.