Optimizing Installation and Cooling Management of High-Power Graphite Electrodes Under International Metallurgical Standards

11 01,2026

Industry Research

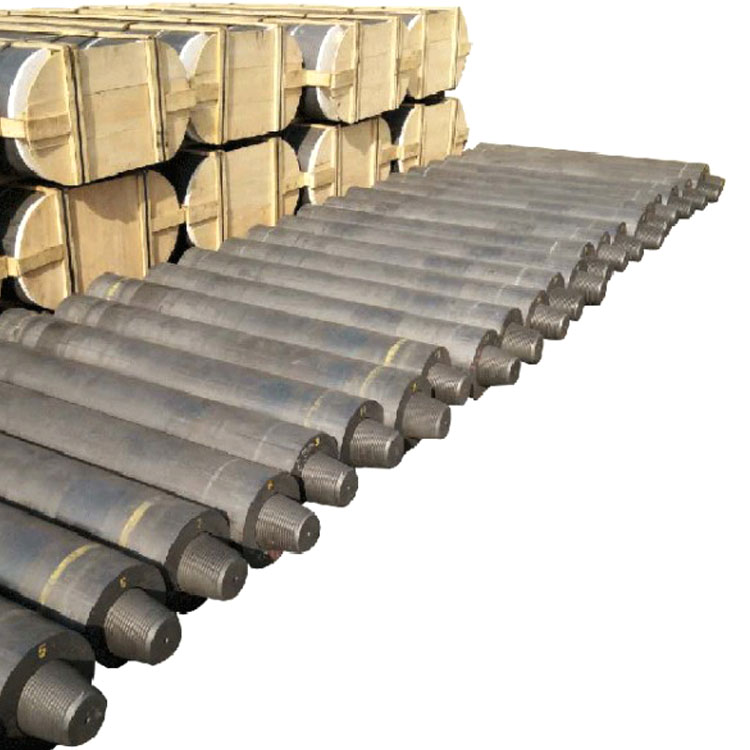

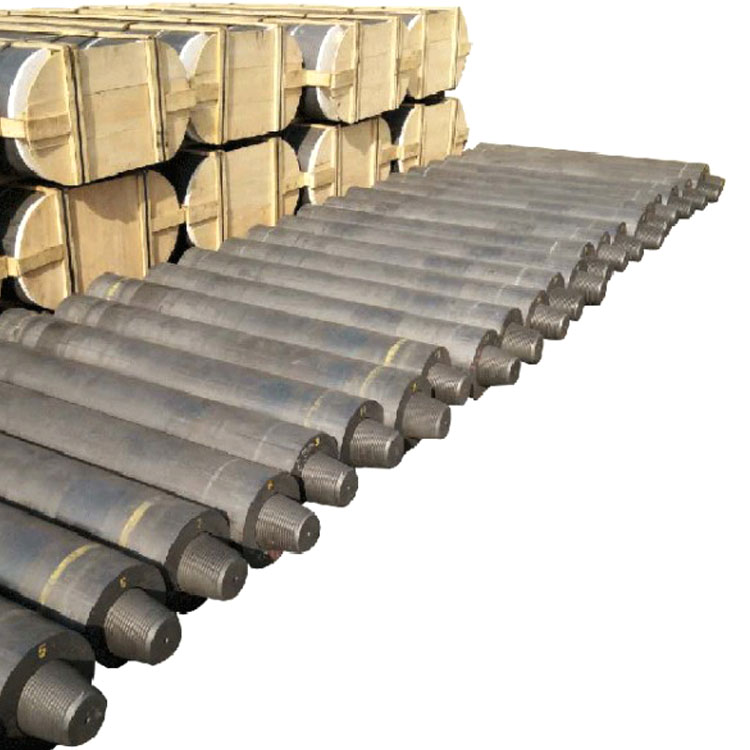

This article addresses common failure issues of high-power graphite electrodes in continuous electric arc furnace operations, including end spalling, sidewall cracking, and joint loosening. By integrating international metallurgical standards such as ISO and ASTM with practical cases from global steel plants, it analyzes the core causes: thermal stress concentration, oxidation corrosion, and mechanical impact. The paper proposes actionable optimization strategies, including precise heating rate control, uniform clamping force application, enhanced cooling system management, and introduction of online condition monitoring. Supported by comparative data and onsite imagery, the study helps users establish electrode health assessment frameworks, significantly extending service life, reducing unplanned downtime, and improving smelting efficiency and cost control.

Optimizing High-Power Graphite Electrode Installation & Cooling Management Under International Metallurgical Standards

Have you ever encountered premature failure in high-power graphite electrodes during electric arc furnace (EAF) operations? Typical problems including end peeling, sidewall cracking, and joint loosening significantly disrupt steel production, increase downtime, and inflate operational costs. Leveraging international metallurgical standards such as ISO 12824 and ASTM A751, combined with practical insights from European and Asian steel producers, this article delves into the root causes and presents actionable optimization strategies for your graphite electrode management.

1. Decoding Common Failure Modes & Their Impacts

The most frequent failure modes in high-power graphite electrodes include:

- End surface peeling: leading to uneven arc formation and reduced furnace efficiency.

- Sidewall cracking: causing sudden breakage risks and potential hazards during handling.

- Joint loosening: resulting in unstable electrical contact and increased resistance losses.

These issues not only degrade electrode lifespan by up to 40% but also cause unplanned shutdowns, jeopardizing your production schedule.

2. Understanding the Underlying Failure Mechanisms

Three core factors contribute to electrode degradation:

- Thermal stress concentration: Rapid temperature variations produce differential expansion, creating microcracks.

- Oxidative corrosion: Exposure to oxygen and furnace atmosphere erodes the graphite surface, weakening structural integrity.

- Mechanical shocks: Impacts during installation or operational vibrations exacerbate existing flaws.

Together, these mechanisms accelerate failure progression if not properly managed.

3. Diagnosing Process & Operational Factors

Common process missteps identified include:

- Excessively rapid temperature ramp-up: exceeding recommended 5°C per minute elevates thermal shock risk.

- Uneven clamp force: inconsistent pressure across electrode surfaces causes localized stress points.

- Inadequate cooling water flow or temperature control: failing to maintain optimal 15-25°C coolant temperature leads to overheating spots.

Recognizing and rectifying these areas is key to reducing premature failures.

4. Aligning With International Metallurgical Standards

“ISO 12824 Section 5.3 emphasizes controlled heating protocols and regular clamp force calibration to ensure electrode stability. ASTM A751 recommends stringent cooling water quality and flow rate monitoring to prevent thermal damage.”

Adhering to these standards mitigates risk and standardizes operational excellence across your facilities.

5. Practical Optimization Measures for Installation and Cooling

To address and prevent failures, consider implementing the following evidence-based solutions:

- Precise temperature control: Use programmable ramping heaters to limit temperature changes within 5°C/min.

- Uniform clamping force: Calibrate hydraulic clamps to evenly distribute pressure, maintaining forces between 8-12 MPa.

- Enhanced cooling circuit management: Integrate flow meters and temperature sensors to continuously track water flow (minimum 15 L/min) and temperature (<25°C).

- Installation angle adjustments: Fine-tuning the electrode’s vertical alignment within ±2° reduces asymmetric thermal expansion.

- Infrared thermography: Employ IR cameras for real-time surface temperature mapping, catching hotspots before damage occurs.

These measures not only extend electrode service life but also improve operational safety.

6. Proof of Effectiveness: European Steel Plant Case Study

A leading steel manufacturer in Germany implemented these optimized installation and cooling procedures over a 6-month period. Key outcomes included:

| Metric |

Before Implementation |

After Implementation |

Improvement |

| Electrode service life (hours per furnace) |

280 |

364 |

+30% |

| Unplanned downtime (hours/month) |

12 |

5 |

-58% |

| Maintenance labor cost savings |

$15,000 |

$9,000 |

-40% |

7. Building a Comprehensive Electrode Health Assessment System

Moving from reactive repair to proactive maintenance requires a robust health scoring model combining:

- Thermal profile analytics from IR sensors

- Clamping force uniformity indexes

- Real-time cooling system efficiency metrics

- Visual inspections and microcrack detection imaging

This data-driven approach empowers operational teams to predict and preempt failures, maximizing uptime and cost-effectiveness.

By consistently applying these insights and aligning with global standards, your electric arc furnace operations can achieve unprecedented reliability and efficiency.