In the ultra - high power electric arc furnaces (EAF) with a diameter exceeding 500mm, the choice of graphite electrodes directly impacts furnace efficiency and operating costs. This article delves deep into the key role of needle coke raw materials in conductivity and thermal stability, details how precision machining and threaded connection design enhance mechanical strength and joint reliability, and presents real - world case studies to illustrate a 15% energy - saving benefit after optimized electrode selection.

EAF steel enterprises often face challenges such as high energy consumption, low furnace efficiency, and unstable electrode performance. These issues not only increase production costs but also affect the quality and quantity of steel production. The combination of materials science and engineering practice is crucial in addressing these pain points.

The quality of raw materials significantly influences electrode performance. Needle coke, as a high - quality raw material for graphite electrodes, offers excellent conductivity and thermal stability. In contrast, traditional electrodes may show poor performance during thermal cycling. For example, in a series of thermal cycle tests, traditional electrodes experienced a 20% reduction in conductivity after 100 cycles, while high - power electrodes made from needle coke only had a 5% reduction.

| Electrode Type | Conductivity Reduction after 100 Thermal Cycles | Thermal Stability |

|---|---|---|

| Traditional Electrodes | 20% | Poor |

| High - Power Electrodes (Needle Coke) | 5% | Excellent |

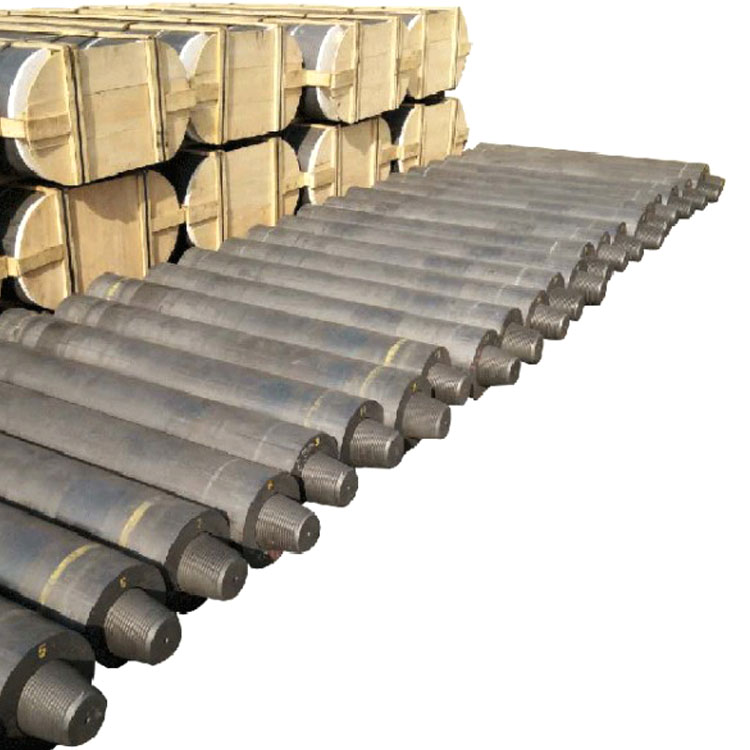

The threaded end design of graphite electrodes plays a vital role in installation efficiency, conductive stability, and fatigue resistance. A well - designed threaded connection can reduce installation time by up to 30%. Moreover, it ensures a more stable current conduction path, as shown in the following information chart (IMAGE - URL2). The unique threaded design also enhances the electrode's ability to withstand mechanical stress during operation, reducing the risk of electrode breakage.

One of our clients, a large - scale EAF steel enterprise, replaced their traditional electrodes with our high - performance graphite electrodes with optimized threaded connections. After a six - month trial period, they achieved a 15% reduction in energy consumption and a 10% increase in furnace efficiency. The following is a quote from their technical director:

"The new electrodes have significantly improved our production efficiency and reduced our energy costs. The threaded connection design is very reliable, and we have experienced fewer electrode failures."

To help steel engineers and technicians better manage their electrodes, we provide a daily inspection checklist. This checklist includes items such as electrode surface condition, threaded connection tightness, and current distribution. Regular use of this checklist can help detect potential problems early and ensure the long - term stable operation of the EAF.

There is a common misconception in the industry that "bigger is better" when it comes to electrode selection. However, in reality, the size of the electrode is not the only factor affecting furnace efficiency. As mentioned earlier, the reliability of the connection and the consistency of heat conduction are more important. Our high - performance graphite electrodes prove that a well - designed electrode can achieve better results even with a smaller size.

In conclusion, the selection of graphite electrodes is a critical decision for EAF steel enterprises. By choosing high - performance electrodes made from needle coke and with optimized threaded connections, steel engineers and technicians can achieve more efficient and green production. If you want to learn more about how to optimize your electrode selection and achieve energy - saving and efficiency - improving goals, click here to explore our solutions.