High - power graphite electrodes play a crucial role in the steel - making process within electric arc furnaces. Their thermal shock performance is a key factor that affects the stability of the production process and the service life of the electrodes. This article will comprehensively analyze the factors influencing the thermal shock performance of high - power graphite electrodes and provide practical preventive maintenance strategies.

The purity of electrode materials has a significant impact on their thermal shock performance. High - purity graphite materials can better withstand the rapid temperature changes in the electric arc furnace. For example, electrodes with a graphite purity of over 99% generally have a 15% - 20% longer service life compared to those with a purity of around 95%. The formulation ratio of the electrode materials, such as the proportion of different carbonaceous raw materials, also affects their thermal shock resistance. A well - formulated electrode can reduce the risk of cracking and breakage during thermal cycling.

The baking and graphitization processes are critical for determining the quality of graphite electrodes. Proper baking can eliminate volatile substances in the electrode material, improving its density and strength. The graphitization process transforms the carbon structure into a graphite - like structure, enhancing the electrical and thermal conductivity of the electrode. For instance, electrodes that have undergone a high - temperature graphitization process at around 2800°C - 3000°C show better thermal shock resistance and electrical performance compared to those graphitized at lower temperatures.

Furnace temperature fluctuations are one of the main factors causing electrode damage. Sudden temperature changes can generate large thermal stresses in the electrode, leading to cracking and breakage. Studies have shown that when the furnace temperature fluctuates by more than 200°C within a short period, the probability of electrode damage increases by 30% - 40%. Current density distribution also affects electrode consumption and damage patterns. Uneven current distribution can cause local overheating, accelerating electrode wear and increasing the risk of breakage.

Good maintenance and upkeep habits can significantly extend the service life of graphite electrodes. Regularly checking the electrode connection status, ensuring proper tightening of the joints, and cleaning the electrode surface can reduce the risk of poor contact and local overheating. In addition, monitoring the electrode's consumption rate and replacing electrodes in a timely manner can also improve production efficiency. For example, steel enterprises that implement a strict electrode maintenance system can reduce electrode consumption by about 10% - 15%.

To scientifically evaluate the thermal shock performance of graphite electrodes, several key indicators need to be considered, such as thermal expansion coefficient, thermal conductivity, and flexural strength. These indicators can be measured through laboratory tests. For example, the thermal expansion coefficient can be measured using a dilatometer, and the thermal conductivity can be measured using a thermal conductivity meter. By regularly testing these indicators, steel enterprises can timely detect potential problems with the electrodes and take preventive measures.

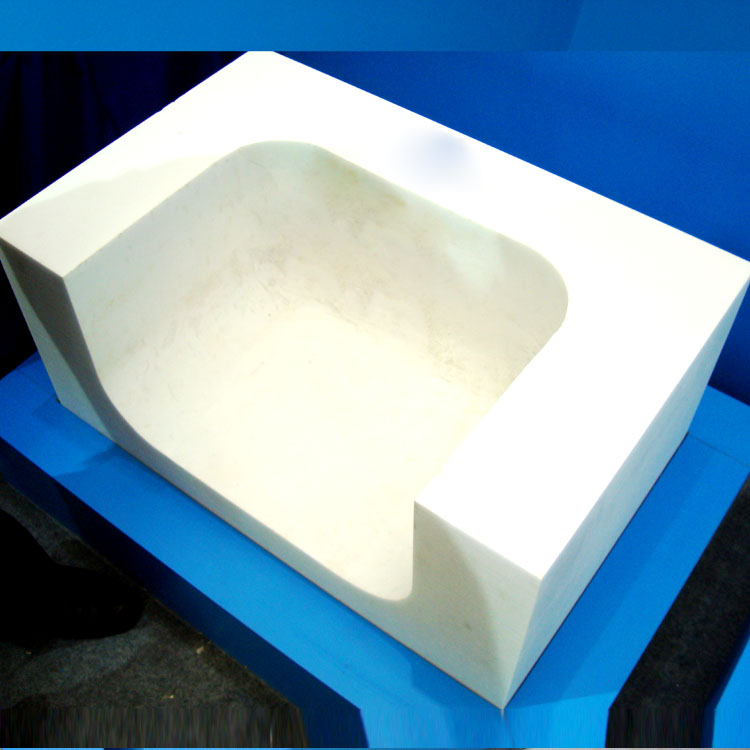

Based on the above analysis, the following preventive maintenance strategies can be adopted: optimizing the power - on curve to avoid sudden large - scale current changes; regularly testing the electrode porosity and thermal shock indicators; and establishing a strict electrode inspection and replacement system. A preventive maintenance flow chart is shown below, which can help steel enterprises better manage the use and maintenance of graphite electrodes.

We understand that you may have many questions about the thermal shock performance of high - power graphite electrodes. To enhance user participation and interaction, we have set up an interactive Q&A section. You can leave your questions in the comments section, and our experts will answer them as soon as possible. In addition, we also regularly hold online seminars on graphite electrode technology and application. Sign up now to participate in these valuable events and gain in - depth knowledge from industry experts.

In conclusion, high - power graphite electrodes are essential components in electric arc furnaces. By understanding the factors influencing their thermal shock performance and adopting scientific preventive maintenance strategies, steel enterprises can improve the stability of the production process, reduce costs, and enhance production efficiency. If you want to learn more about high - quality graphite electrodes and how to optimize their use, please click the link below:

Discover High - Quality Graphite Electrodes Now!