The steel industry’s relentless drive for higher efficiency and greener operations underscores the critical role of graphite electrodes in ultra-high power electric arc furnaces (EAF). Selecting appropriate electrodes founded on furnace type and current density transcends convention—scientific and data-backed methodologies unlock operational stability and cost reductions. This technical discourse unpacks prevalent misconceptions in electrode choice and maps out guidelines enhancing performance and sustainability within EAF environments.

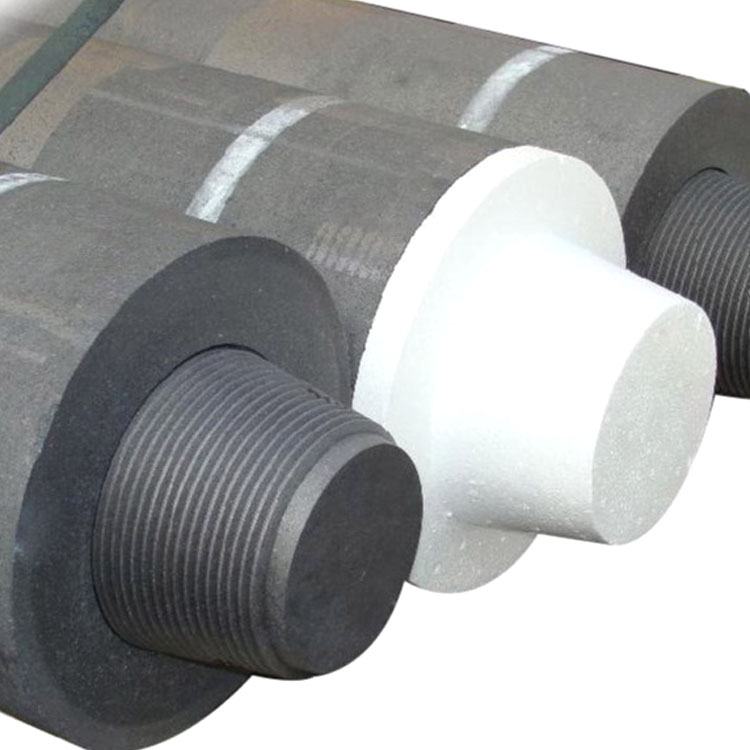

Quality needle coke forms the cornerstone of superior graphite electrodes, imbuing them with exceptional electrical conductivity and mechanical resilience. High-grade needle coke enables a uniform crystalline structure, minimizing resistivity to values typically below 6 μΩ·m, significantly outperforming generic raw materials. Coupled with precision machining—achieving dimensional tolerances within ±0.1 mm and optimized end threading—these electrodes ensure robust mechanical connections that withstand thermal stress and electromagnetic loads inherent to EAF operations.

Intrinsically, the electrode’s mechanical performance depends on the integrity of its threaded joints, which must sustain tensile strengths upwards of 30 MPa to prevent slippage or fracturing during peak currents exceeding 150 kA. Advanced manufacturing techniques employing CNC machining and controlled thermal treatments solidify this critical reliability.

One pervasive error involves misaligning electrode diameter selection with furnace capacity and operational current density, directly impairing energy efficiency. For ultra-high power EAFs operating at current densities around 35–45 A/cm2, selecting electrodes with diameters adhering to rigorous compatibility charts—often ranging between 500 mm and 650 mm—is paramount.

Table 1 outlines typical recommended electrode sizes relative to furnace rating and associated current densities, reflecting industry best practices:

| Furnace Power (MW) | Current Density (A/cm²) | Recommended Electrode Diameter (mm) |

|---|---|---|

| 50–75 | 30–35 | 400–500 |

| 75–100 | 35–40 | 500–550 |

| >100 | 40–45 | 550–650 |

Overlooking this alignment often results in premature electrode wear or energy inefficiencies, with studies citing up to 12% unnecessary energy consumption attributed solely to incorrect sizing. Optimal electrode diameter selection amplifies electric conductivity and reduces power losses, potentially lowering energy usage by 5–8% in operational scenarios.

A leading steelmaker benchmarked a transition from conventional electrodes to high-quality needle coke-based graphite with exact sizing matched to their 110 MW EAF units. Post-implementation, the plant recorded approximately 7% reduction in specific energy consumption (kWh/ton of steel), translating into annual cost savings exceeding $400,000. Concurrently, electrode consumption dropped by 9%, underpinning lowered operational expenditures and extended campaign life.

The integrity of electrode joints strongly influences the furnace’s uninterrupted function. Employing refined threading designs—typically double-start threads with precise pitch—ensures mechanical adhesion and electrical continuity. Routine inspections using ultrasonic or dye penetrant testing can preempt potential fractures or joint loosening, safeguarding uptime.

Complementary maintenance tactics include thermal imaging for hotspot detection and electrical resistance measurements at connection points, helping validate electrode health and schedule timely replacements. Implementing these routines has demonstrated a 30% decrease in unplanned maintenance incidents.

Procurement professionals must balance capital expenditure against long-term operational savings when choosing graphite electrodes. Emphasizing needle coke content above 95% and demanding compliance with international standards—such as ISO 10438—can elevate product quality. Advanced brands offer technical support, customized sizing, and post-sales service, collectively reducing total cost of ownership (TCO) and aligning with sustainability goals.