Performance Evaluation of Graphite Electrodes in Electric Arc Furnaces: Guide to Thermal Conductivity and Thermal Shock Resistance

04 02,2026

Tutorial Guide

This article provides a comprehensive guide to evaluating the suitability of high-power graphite electrodes for electric arc furnace (EAF) steelmaking across various steel grades. It focuses on critical performance parameters including thermal conductivity, thermal shock resistance, electrical resistivity, and oxidation resistance. By integrating real operating conditions such as melting temperature, slag composition, and oxygen blowing intensity, the guide assists steel plant users in scientifically selecting electrode grades to minimize consumption and prevent production incidents. Featuring real-world industry case studies, selection flowcharts, and on-site testing methodologies, this tutorial supports precise and efficient decision-making, ultimately enhancing refining quality and equipment lifespan.

Comprehensive Guide to Evaluating High-Power Graphite Electrodes: Thermal Conductivity & Thermal Shock Resistance in EAF Steelmaking

Precision in selecting high-power graphite electrodes is critical to optimizing electric arc furnace (EAF) operations across various steel grades. This tutorial delves into essential performance metrics—thermal conductivity, thermal shock resistance, electrical resistivity, and oxidation resistance—that influence electrode suitability under diverse operational conditions. By analyzing real-world steel mill data and considering factors such as melting temperature, slag composition, and oxygen injection intensity, steel producers can scientifically align electrode choices with process demands, mitigating excessive wear and preventing costly production disruptions.

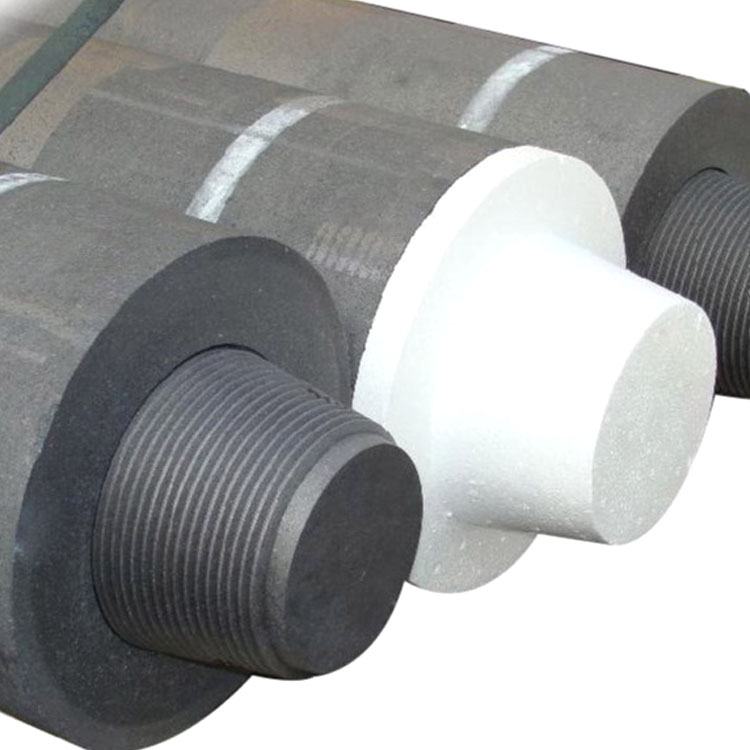

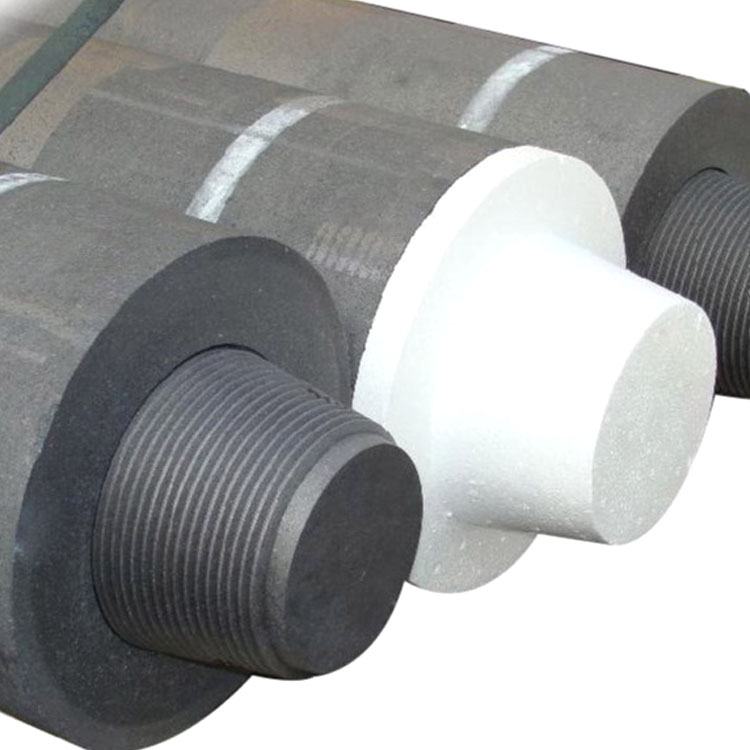

Key Performance Indicators of High-Power Graphite Electrodes

Understanding electrode characteristics is fundamental for optimal matching with steel grades like stainless and alloy steels, which pose distinct challenges due to their process variability.

Thermal Conductivity

Thermal conductivity directly affects the electrode’s ability to dissipate heat generated during arc operation. Typically, high-power graphite electrodes exhibit thermal conductivities ranging from 120 to 160 W/m·K at room temperature. Efficient heat dissipation reduces localized overheating, which is crucial in maintaining electrode integrity and prolonging service life.

Thermal Shock Resistance

Thermal shock resistance (TSR) measures the electrode’s capacity to withstand rapid temperature fluctuations without cracking. It is quantified by controlled thermal cycling tests, where electrodes are subjected to abrupt temperature changes between ambient and extreme operational heat, simulating slag splashes or arc instability. Electrodes with TSR values above 150 cycles typically ensure robustness in fluctuating furnace environments.

Electrical Resistivity and Oxidation Resistance

Electrical resistivity influences energy consumption and heat generation within the electrode itself. High-power electrodes typically maintain resistivity in the range of 11-15 µΩ·m at operational temperatures. Lower resistivity reduces joule heating but must balance against mechanical strength. Oxidation resistance, enhanced via impregnation or coatings, slows degradation caused by high-temperature exposure to atmospheric oxygen, preserving electrode geometry and conductivity over longer cycles.

Steel Grade-Specific Matching Considerations

Different steel grades impose unique thermal and chemical stresses on electrodes:

- Stainless Steel: Requires electrodes with superior oxidation resistance due to aggressive slag chemistries rich in chromium oxides.

- Alloy Steel: Demands high thermal shock resistance to accommodate rapid temperature cycling during diverse alloying processes.

- Carbon Steel: Standard electrodes with balanced thermal properties are often sufficient, but optimized resistivity can reduce energy costs.

Practical Evaluation & Selection Workflow

The electrode selection process should follow a structured workflow, grounded in precise testing and operational parameters:

- Identify Steel Grade and Process Requirements: Collate melting temperature range, slag chemistry, and oxygen blow intensity.

- Conduct Lab Testing: Measure electrical resistivity, thermal conductivity, and TSR under simulated furnace conditions.

- Onsite Trial & Monitoring: Implement selected electrodes in pilot melts; monitor wear rates, energy consumption, and arc stability.

- Data Analysis & Optimization: Analyze trends and adjust electrode specifications accordingly.

Common Pitfalls of Electrode Misapplication

Multiple case studies reveal that inappropriate electrode selection can drastically increase consumption rates and operational hazards:

- Overheating and Premature Fragmentation: Using electrodes with low thermal conductivity in high heat flux environments leads to cracking and frequent replacements.

- Increased Electrical Losses: High resistivity electrodes in processes demanding rapid thermal cycling cause energy inefficiencies and voltage instability.

- Oxidation-Induced Wear: Neglecting oxidation resistance in slag-rich furnaces shortens electrode life and compromises melt quality.

Recognizing these risks underscores the value of methodical electrode evaluation and tailored selection aligned with operational nuances.