For metallurgical engineers and production managers in electric arc furnace (EAF) operations, minimizing graphite electrode consumption isn’t just about cost—it’s about stability, efficiency, and sustainability. Recent field studies show that improper current density management alone can increase electrode wear by up to 25–30%, while uncontrolled temperature fluctuations may shorten electrode life by another 15–20%. This article breaks down how these two critical factors interact—and how you can use real-time data and preventive maintenance to optimize performance.

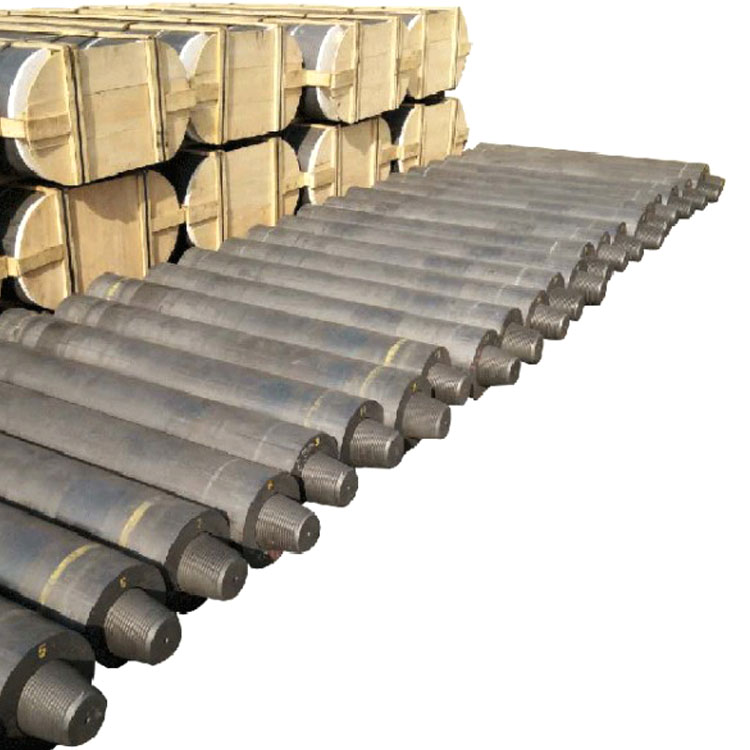

High-power graphite electrodes are designed for high thermal conductivity and mechanical strength, but their lifespan hinges heavily on consistent current distribution. When current density exceeds 15 A/cm² at the tip (a common issue in poorly balanced furnaces), localized overheating accelerates oxidation and cracking—especially in lower-grade electrodes with higher porosity.

Case Study: A steel plant in Turkey reduced electrode consumption by 22% after implementing a dynamic current control system based on real-time monitoring. By adjusting input power to maintain an average current density of 12–14 A/cm² across all three electrodes, they extended average electrode life from 18 hours to 22 hours per batch.

Laboratory tests reveal that even a ±150°C variation in furnace temperature during a single melting cycle increases the risk of thermal shock-induced fractures by over 40%. These micro-cracks propagate under repeated heating/cooling cycles, leading to premature breakage or excessive dusting—a major source of both material loss and downtime.

Pro Tip: Use infrared thermography to map hotspots around the electrode tip every 2–3 shifts. If temperatures exceed 2,200°C consistently, it's time to review your scrap loading pattern or consider switching to ultra-high-purity electrodes (≥99.5% carbon).

These steps aren't just theoretical—they’re proven in plants across China, India, and Brazil where we’ve partnered with EAF producers to reduce electrode waste by an average of 18–27% within six months of adopting our recommended protocols.

If your team is still relying on reactive fixes instead of proactive strategies, now is the time to shift focus. Our premium high-power graphite electrodes—engineered for extreme thermal stability and low consumption—are trusted by global steelmakers who demand reliability under pressure.

Explore Our High-Power Electrodes Today →

Want to see how this works in your own operation? Join our upcoming free webinar on “Advanced Electrode Management for Steelmakers” — limited spots available. No fluff. Just actionable insights backed by real-world results.