Field Testing Methods to Verify Graphite Electrode Compatibility with Specific Steel Grades

01 02,2026

Application Tips

This article presents practical field testing techniques to effectively determine the suitability of high-power graphite electrodes for specific steel grade refining requirements. By analyzing key performance indicators such as thermal conductivity, oxidation resistance, thermal shock resistance, and electrical resistivity under typical electric arc furnace conditions, it provides a comprehensive understanding of the electrode demands posed by different steel grades. Leveraging real-world operational data, the article outlines a scientific selection process alongside actionable testing procedures to ensure accurate electrode matching. Additionally, it highlights common misuse cases with preventive recommendations to help steel plants improve selection accuracy and mitigate production risks. Structured content supported by visual aids facilitates informed technical decisions, enhancing electrode utilization efficiency and refining stability in steel production.

How to Determine if High-Power Graphite Electrodes Suit Specific Steel Grades Through On-Site Testing

In the steelmaking industry, selecting the optimal high-power graphite electrode for specific steel grades is crucial to maximizing arc furnace efficiency and ensuring stable production. This article explores effective on-site testing methods that refine electrode selection by analyzing critical performance parameters such as thermal conductivity, oxidation resistance, thermal shock resistance, and electrical resistivity. Real-world plant conditions—including melting temperature, slag composition, and oxygen blowing intensity—are incorporated to correlate steel grades with electrode requirements, guiding steel manufacturers towards scientifically sound decisions.

Key Performance Indicators for Electrode Compatibility

Electrode performance fundamentally influences steel quality and operational uptime. The following parameters are essential indicators to evaluate:

- Thermal Conductivity: High thermal conductivity enhances heat dissipation, minimizing thermal gradient-induced damage. For high-power electrodes, values above 100 W/m·K at ambient temperature optimize arc stability within electric arc furnaces operating typically between 1600°C and 1800°C.

- Oxidation Resistance: Oxidation leads to premature electrode consumption. Effective electrodes maintain less than 0.5% weight loss during exposure at 600°C for 20 hours in oxidizing atmospheres common in steel plants.

- Thermal Shock Resistance: This indicates electrode capacity to withstand rapid temperature changes invoked by slag interaction or oxygen blowing. Electrodes with a thermal shock resistance (measured as spalling rate under standard quenching tests) below 15% are recommended for aggressive melting conditions.

- Electrical Resistivity: Lower electrical resistivity reduces energy losses, typically requiring values under 15 μΩ·m to guarantee optimal power transmission during melting.

Matching Electrodes to Steel Grade Requirements

Different steel grades impose unique demands on electrode properties:

| Steel Grade |

Melting Temperature (°C) |

Electrode Focus |

Recommended Electrode Traits |

| Low Alloy Steel |

1450 - 1550 |

Stable electrical conductivity |

Moderate thermal conductivity, robust electrical resistivity & oxidation resistance |

| Stainless Steel |

1550 - 1650 |

High oxidation resistance due to aggressive slag |

Enhanced anti-oxidation coatings, superior thermal shock resistance |

| High Carbon Steel |

1600 - 1700 |

Elevated thermal stress and electrical stability |

Maximized thermal conductivity, low electrical resistivity |

| Tool Steel |

1650 - 1800 |

Resilience to thermal shock and oxidation |

Superior thermal shock resistance, high purity graphite to minimize resistivity |

Practical On-Site Testing Methods and Flow

To verify electrode suitability under actual production conditions, steel plants employ the following testing workflow:

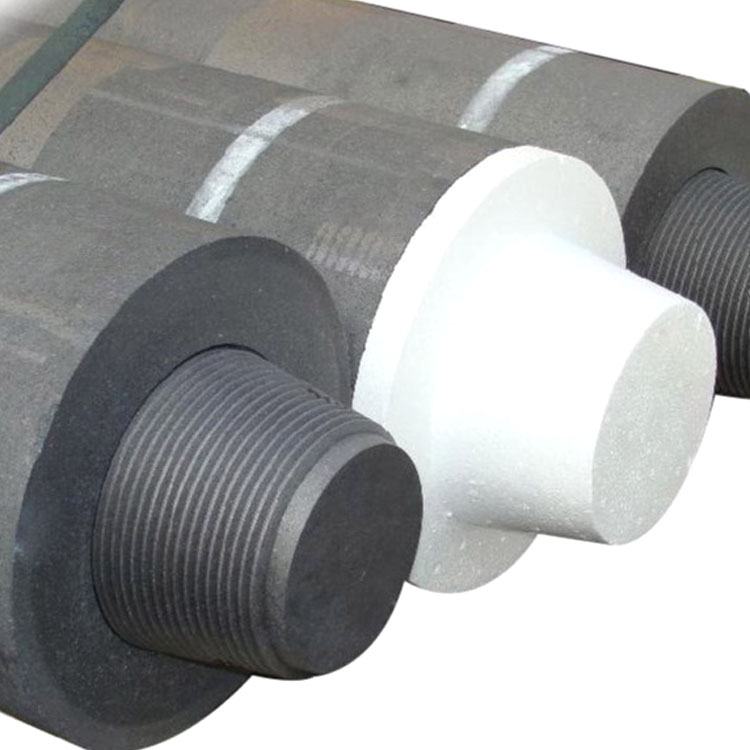

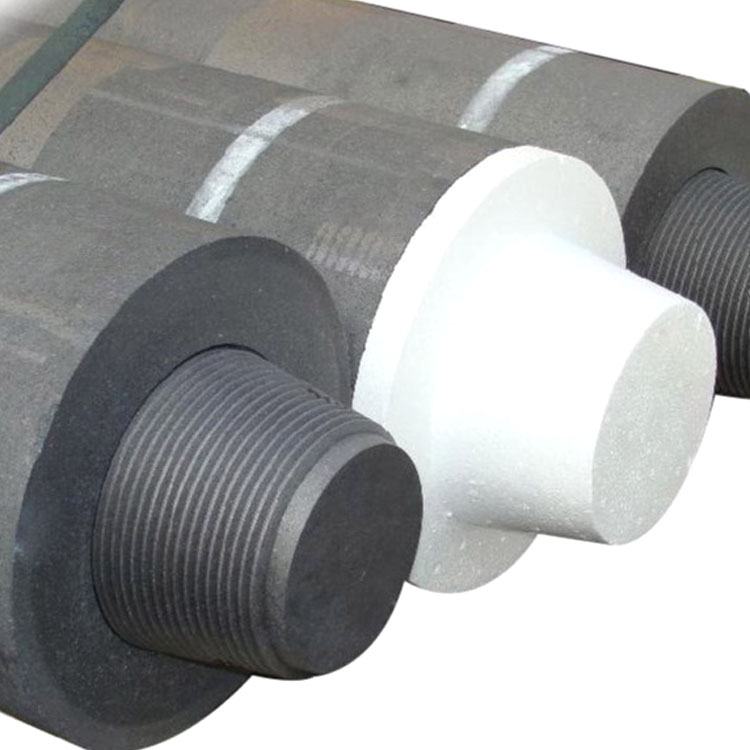

- Visual Inspection: Check for surface defects, porosity, and uniform density of electrodes prior to installation.

- Electrical Resistivity Measurement: Utilize a four-point probe technique to record resistivity; values must align with electrode specification sheets.

- Thermal Shock Resistance Test: Conduct quenching tests by rapidly shifting electrode samples from 1500°C to ambient water bath, counting spall cracks.

- Oxidation Behavior Assessment: Expose electrode samples in situ to furnace atmosphere at operating temperatures and measure weight loss over predefined periods.

- Arc Stability Monitoring: Observe real-time arc voltage fluctuations during melting to gauge electrode performance under load (voltage variance within ±5 V recommended).

Common Misapplications and Risk Mitigation

Misaligning electrode properties with steel grade requirements can lead to production disruption and equipment damage:

- Excessive Electrode Consumption: Using electrodes with poor oxidation resistance in stainless steel production accelerates wear, increasing electrode change frequency by over 30%.

- Arc Instability: Improper electrical resistivity levels cause arc fluctuations, leading to inconsistent steel chemistry and reduced yield.

- Thermal Shock Damage: Electrodes with inadequate thermal shock resistance crack or spall under rapid cooling, jeopardizing furnace uptime.

Key preventative measures include routine on-site testing, adherence to steel grade-electrode compatibility charts, and integration of user feedback into electrode quality control.

Leveraging Structured Data & Visual Tools for Decision-Making

Structured test data combined with visual aids such as flowcharts reinforce the selection process and minimize human error. The following illustrates a simplified electrode selection flow:

This systematized approach enhances precision in identifying suitable electrodes, reducing unplanned furnace downtime by up to 20% when rigorously applied.