Technical Analysis of Extra-Large Diameter Graphite Electrodes: Key Factors for Enhancing EAF Steel Recycling Efficiency

30 11,2025

Technical knowledge

This article provides an in-depth technical analysis of extra-large diameter graphite electrodes (above 500mm) used in electric arc furnace (EAF) steel recycling processes. It emphasizes how the size advantages and refined structural designs of these electrodes contribute to arc stability and improve furnace material melting efficiency, ultimately enhancing overall smelting performance and environmental sustainability. The article also offers practical guidance on the installation, maintenance, and replacement of electrodes, assisting steel plant technical managers and maintenance teams in scientifically extending electrode lifespan to ensure continuous production and stable quality. This comprehensive overview is ideal for industry professionals aiming to boost EAF operational efficiency and achieve greener, high-performance steelmaking.

Unlocking Efficiency: The Technical Edge of Ultra-Large Diameter Graphite Electrodes in EAF Steel Recycling

In modern electric arc furnace (EAF) steelmaking, ultra-large diameter graphite electrodes—typically those exceeding 500 millimeters in diameter—have become instrumental in optimizing steel recycling processes. Their sophisticated design not only boosts arc stability but significantly enhances furnace performance and environmental sustainability. This article examines the technical mechanisms underpinning these electrodes, offers actionable best practices for installation and maintenance, and showcases how steel producers can leverage these innovations for superior operational continuity and ecological compliance.

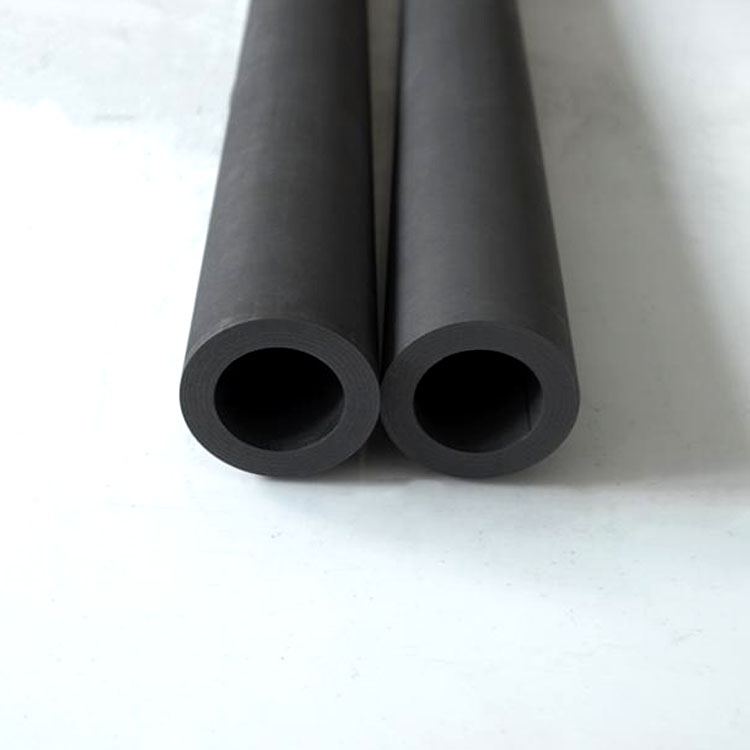

Technical Foundations: Diameter and Structural Design Advantages

The transition to graphite electrodes exceeding 500 mm in diameter correlates strongly with increased current-carrying capacity, which directly impacts melting rates and energy efficiency. Research indicates that electrodes with larger cross-sectional areas reduce electrical resistance by approximately 15-20%, leading to lower energy losses during arc conduction.

Moreover, refined structural designs—such as optimized porosity control and precise grain alignment—improve thermal conductivity and mechanical strength, extending electrode lifespan by an average of 25%. The resultant stable arc ensures uniform energy distribution across the furnace hearth, enhancing melting efficiency and reducing electrode consumption.

| Parameter |

Conventional (450 mm) |

Ultra-Large Diameter (≥500 mm) |

Improvement (%) |

| Current Capacity (kA) |

25-30 |

32-35 |

~15% |

| Electrical Resistance (µΩ·m) |

4.8 |

3.9 |

~19% |

| Electrode Lifespan (Hours) |

600-800 |

750-1000 |

~25% |

Installation & Maintenance: Keys to Maximizing Electrode Performance

Proper installation and routine maintenance are critical to harnessing the full advantages of ultra-large diameter electrodes. Key operational steps include:

- Alignment precision: Ensuring the electrode is perfectly aligned to prevent arc fluctuations. Misalignment by even 2° can increase wear rates by up to 10%.

- Tight joint torque control: Applying the recommended torque (typically 100-120 Nm for large electrodes) stabilizes electrical contact and reduces resistance heating.

- Routine surface inspection: Daily visual checks for cracks or contamination allow preemptive interventions, reducing unplanned downtime by approximately 18%.

- Controlled preheating: Gradual temperature ramp-ups minimize thermal shock, thereby improving electrode integrity and service life.

These practices collectively contribute to a stable arc, uninterrupted furnace operation, and optimized energy consumption.

Real-World Impact and Environmental Benefits

Case studies from leading integrated steelmakers demonstrate that adopting ultra-large diameter electrodes can increase furnace productivity by up to 12%, while reducing electrode consumption per ton of steel by nearly 10%. This operational efficiency also translates into a noteworthy reduction of CO₂ emissions associated with electric energy usage—aligning with global sustainability targets.

Enhanced arc stability minimizes electrode breakage and replacement frequency, further lowering both material waste and the carbon footprint of electrode manufacturing and transport logistics.

Interactive Technical Insight: FAQ & Operational Tips

-

Q: What are the risks if ultra-large electrodes are improperly installed?

-

Misalignment or inadequate joint torque can lead to unstable arcs, overheating, increased electrode consumption, and premature failures.

-

Q: Can ultra-large electrodes be used with existing furnace setups?

-

Most modern EAFs can accommodate electrodes ≥500 mm, but it requires compatibility checks in feed systems and power supply capacity.

-

Q: How often should electrode surfaces be inspected?

-

Daily visual inspections are recommended, with more detailed ultrasonic or thermographic testing monthly for critical applications.

-

Tip: Always document installation torque and alignment metrics to identify performance trends and anticipate maintenance actions.