In the steel industry, the durability of high-power graphite electrodes in electric arc furnaces (EAFs) directly affects operational costs and production continuity. Understanding the intricate roles of electrode material purity and baking performance can unlock pathways to significant lifetime extension and performance stability.

The lifespan of high-power graphite electrodes often varies widely across steel plants, sometimes differing by as much as 25-30%. This inconsistency leads to unexpected downtime, increased electrode replacement expenses, and higher scrap rates. Steelmakers increasingly seek in-depth technical insights that bridge raw material properties and process parameters to optimize electrode durability effectively.

Elemental impurities such as sulfur, alkali metals, and iron oxides within the raw carbon matrix elevate electrical resistivity and reduce thermal shock resistance. For instance, increasing total impurity content from 0.2% to 0.5% can raise the resistivity by approximately 15%, impairing electrical conductivity crucial for furnace performance.

Baking process control—especially maintaining steady temperature gradients during carbonization—dramatically influences pore structure uniformity. Optimized baking temperature profiles minimize micropores and cracking, thus improving mechanical strength by up to 20%. Additionally, advanced graphitization at temperatures exceeding 2800°C enhances the lattice structure, significantly boosting thermal conductivity and shock tolerance.

Operational fluctuations like irregular furnace temperature cycles and uneven current density distribution increase localized electrode stress, accelerating consumption rates. Case studies reveal that frequent temperature spikes over 10°C cause microfractures, raising wear speed by up to 18%. Moreover, inconsistent maintenance practices, such as delayed cleaning or inadequate electrode monitoring, compound these effects, shortening electrode lifespan by months.

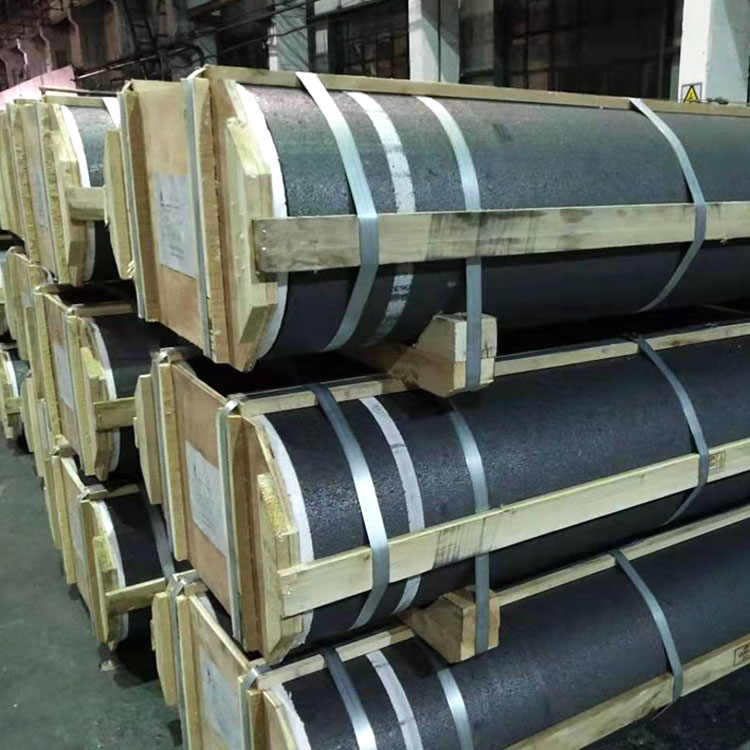

Empirical data collected from multiple steelworks indicate a clear correlation between raw material quality, baking precision, and electrode performance. Electrodes produced with stricter impurity thresholds (<0.3%) and controlled baking cycles demonstrated a 30% lower average consumption rate versus standard products. Notably, fractures inflicted by thermal shocks showed predominantly transverse crack patterns, whereas oxidation damage typically exhibited longitudinal fissures, guiding targeted interventions.

“Electrode purity and controlled baking are pivotal to optimizing current conduction and mechanical resilience. Our data affirm that even small improvements here yield substantial reductions in downtime and cost.” — Dr. Mark Stevens, Senior Metallurgy Consultant

These strategies form the backbone of a systemic approach to electrode lifecycle management, integrating material science with furnace operational protocols.