Imagine a steel plant facing significant losses during furnace shutdowns. These interruptions not only lead to production delays but also incur substantial costs. In the steel - making industry, the choice of graphite electrodes for Electric Arc Furnaces (EAFs) plays a pivotal role in determining the efficiency and energy consumption of the entire process.

Needle coke is a crucial raw material for high - power graphite electrodes. Its unique structure endows the electrodes with excellent electrical conductivity and thermal stability. When the carbon atoms in needle coke are arranged in a highly ordered manner, they facilitate the smooth flow of electric current, reducing energy loss during the conduction process. Research shows that electrodes made from high - quality needle coke can improve the conductivity of the electrodes by up to 20%, significantly enhancing the efficiency of the EAF.

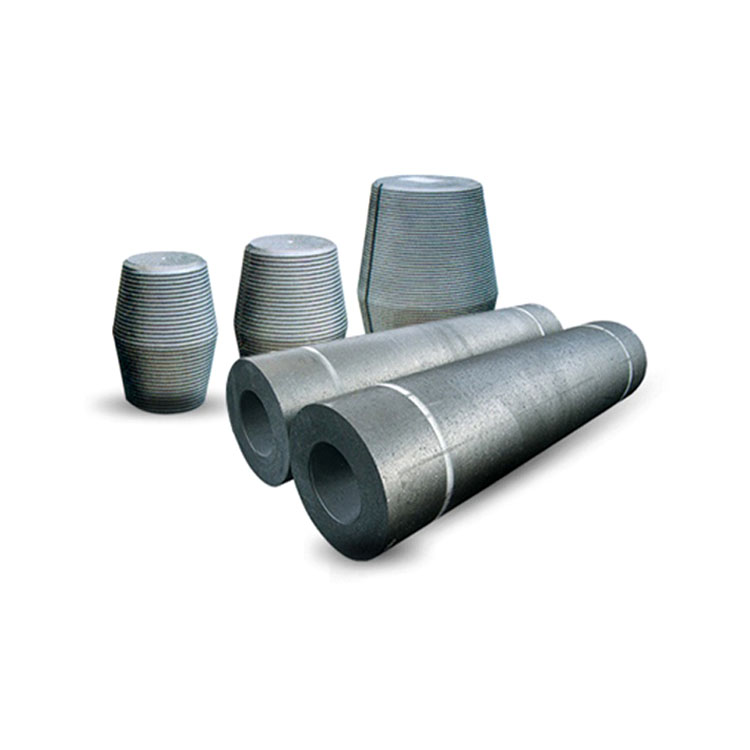

Precision machining and well - designed end threads are equally important. High - precision machining ensures that the electrodes have consistent dimensions, which is essential for maintaining mechanical strength. The end thread design, on the other hand, guarantees reliable connections between electrodes. A well - designed thread can withstand high - temperature and high - pressure environments during the operation of the EAF, preventing electrode breakage and loosening. For example, a properly machined electrode with a precise thread design can increase the mechanical strength of the electrode connection by 15%, ensuring stable operation of the furnace.

A well - known steel enterprise was facing high energy consumption and low efficiency in its EAF operations. After a comprehensive evaluation, the company decided to replace its existing graphite electrodes with high - performance ones. The new electrodes were made from high - quality needle coke and featured advanced processing and thread design. After the replacement, the enterprise witnessed a remarkable 15% increase in the operating efficiency of the EAF and a significant reduction in energy consumption. This not only saved production costs but also contributed to more sustainable and environmentally friendly steel - making practices.

One common misconception is that the larger the diameter of the electrode, the better. In fact, the diameter of the electrode needs to be carefully matched with the furnace type and current density. An oversized electrode may not fit the furnace properly, leading to uneven current distribution and increased energy consumption. On the contrary, a properly sized electrode can optimize the current density, improving the overall efficiency of the EAF.

To help EAF operators and procurement decision - makers, we provide a daily inspection checklist and a status evaluation form. These tools can assist in regularly monitoring the condition of the electrodes, identifying potential problems in a timely manner, and ensuring the electrodes are always in the best working condition. For example, by following the daily inspection checklist, operators can detect early signs of electrode wear or damage, preventing costly breakdowns.

Are you curious about whether your electrodes are in the optimal state? You can take our small test: 'Is Your Electrode in the Best Condition?' This interactive element allows you to better understand the performance of your electrodes. When choosing graphite electrodes, it is crucial to select a trustworthy and reliable brand. Our high - performance graphite electrodes offer a cost - effective solution that can help you achieve green and efficient steel - making.