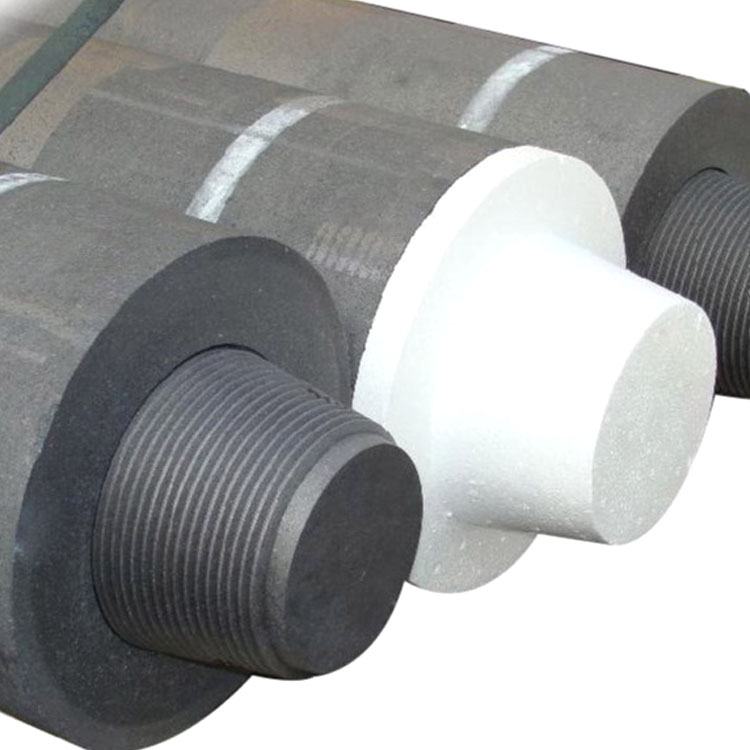

In the realm of electric arc furnace steelmaking, the proper selection of high - power graphite electrodes is crucial for efficient and cost - effective production. This article delves into the core performance parameters of high - power graphite electrodes, such as thermal conductivity, resistivity, thermal shock resistance, and oxidation resistance.

Let's start by understanding the key performance indicators. Thermal conductivity, for example, affects how quickly heat can be transferred within the electrode. A high - power graphite electrode with good thermal conductivity can better withstand the high - temperature environment in the electric arc furnace. Resistivity, on the other hand, is related to the electrical energy conversion efficiency. Lower resistivity means less energy loss during the melting process.

Different steel grades, such as stainless steel, alloy steel, and high - carbon steel, have unique smelting requirements. Stainless steel, for instance, often requires electrodes with high oxidation resistance due to the presence of alloying elements that can accelerate oxidation. Alloy steel may need electrodes with excellent thermal shock resistance because of the complex melting process. High - carbon steel has its own set of challenges, which we will discuss in more detail later.

To select the appropriate electrode, we need to consider practical operating conditions, including the melting temperature range, slag composition, and oxygen - blowing intensity. For example, a higher melting temperature may require an electrode with better high - temperature performance, while a specific slag composition can affect the electrode's corrosion resistance.

A typical misuse case involves high - carbon steel. In some steel mills, conventional power electrodes were used instead of the specialized high - power electrodes for high - carbon steel. This led to frequent power outages and excessive electrode consumption. Tests showed that in a high - carbon steel smelting process with a melting temperature of around 1600 - 1700°C, the conventional power electrode's consumption rate was 30% higher than that of the appropriate high - power electrode. This not only disrupted the production process but also significantly increased the production cost.

We have developed a systematic selection process, which is presented in a flowchart (as shown in the figure). This process takes into account all the factors mentioned above. Additionally, on - site testing methods are provided to help steel mills quickly and accurately select the right electrodes. These methods include measuring the electrode's physical properties on - site and observing its performance during a short - term test run.

Q: How can I quickly determine if the electrode I'm using is suitable for my steel grade?

A: You can refer to the selection flowchart in this article. Also, conducting on - site tests by measuring key performance parameters and observing the electrode's performance during a short - term melting process can give you a quick answer.

Q: What are the potential economic losses caused by electrode misuse?

A: As shown in the high - carbon steel misuse case, electrode misuse can lead to power outages, increased electrode consumption, and production disruptions. These factors can increase production costs by up to 20 - 30%.

By following the guidelines and methods provided in this article, steel mills can make more scientific electrode selection decisions, optimize their production processes, and reduce costs. If you have any further questions about high - power graphite electrode selection or need customized services, please click here to contact our professional team.