In the modern steelmaking industry, ultra-high power electric arc furnaces (EAFs) have become a key technology for efficient and green steel production. Graphite electrodes play a crucial role in EAFs, serving as the conductive medium for the high - power electric arc that melts scrap steel and other raw materials. The performance of graphite electrodes directly affects the efficiency, energy consumption, and maintenance cost of the furnace.

According to industry statistics, a well - selected graphite electrode can reduce energy consumption in EAFs by up to 15% and increase the furnace's operating efficiency by approximately 10%. This not only helps steel manufacturers save production costs but also contributes to environmental protection by reducing energy waste.

Needle coke is the primary raw material for high - quality graphite electrodes. Its unique needle - like structure endows graphite electrodes with excellent conductivity and thermal stability. The high degree of orientation of the needle coke's carbon structure allows for efficient electron flow, resulting in low electrical resistance.

In terms of thermal stability, needle coke can withstand high temperatures without significant deformation or degradation. This is crucial in ultra - high power EAFs, where the electrode tip can reach temperatures of over 3000°C. By using needle coke, the electrode can maintain its shape and performance under extreme thermal conditions, reducing the risk of electrode breakage and improving the overall stability of the furnace operation.

| Property | Graphite Electrode with Needle Coke | Ordinary Graphite Electrode |

|---|---|---|

| Electrical Resistance (μΩ·m) | 10 - 15 | 18 - 25 |

| Thermal Expansion Coefficient (10⁻⁶/°C) | 1 - 3 | 3 - 5 |

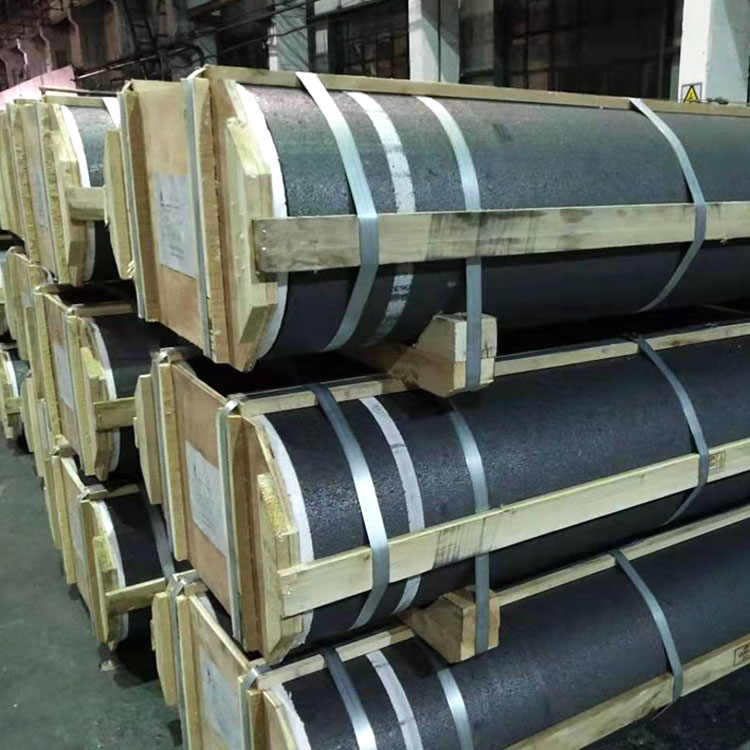

Precision machining is essential for ensuring the mechanical strength of graphite electrodes. Through advanced machining techniques, the electrode's surface finish and dimensional accuracy can be precisely controlled. This reduces stress concentration points on the electrode surface, preventing cracks and fractures during operation.

The end thread design also plays a critical role in electrode connection reliability. A well - designed thread can provide a strong and stable connection between electrodes, ensuring continuous and efficient power transmission. For example, a special thread profile can increase the contact area between electrodes, reducing electrical resistance at the connection point and improving overall conductivity.

Let's take a large - scale steel mill as an example. Before optimizing the electrode selection, the mill's EAF had relatively high energy consumption and frequent electrode replacement requirements. After switching to high - quality needle coke graphite electrodes with advanced machining and thread design, the mill achieved significant improvements.

The energy consumption per ton of steel decreased from 450 kWh to 380 kWh, a reduction of approximately 15.6%. At the same time, the electrode consumption rate decreased from 2.5 kg/ton of steel to 2 kg/ton of steel, saving on raw material costs. In addition, the furnace's operating efficiency increased, allowing for more steel production within the same time frame.

To help steel industry technicians and procurement decision - makers better maintain and assess the condition of graphite electrodes, we provide the following practical tools and checklists:

By following these maintenance and assessment methods, steel manufacturers can ensure the long - term stable operation of their EAFs and further reduce production costs.

Upgrade Your Steel Production with High - Performance Graphite Electrodes!