In modern steelmaking, optimizing ladle insulation thickness while ensuring thermal performance is paramount to achieving significant energy savings and reducing carbon footprint. This article explores how innovations in refractory insulation, particularly the Sunrise vermiculite ladle insulation board, address these challenges by combining low thermal conductivity with superior structural stability.

Conventional insulation materials such as aluminosilicate fibers have been widely used; however, they present several drawbacks. Insufficient drying or baking treatments often lead to high thermal losses and temperature drops exceeding 100°C at the ladle shell, increasing energy consumption drastically. Moreover, thicker insulation layers increase ladle weight and reduce operational flexibility, hindering continuous steelmaking processes.

| Property | Vermiculite-Based Board | Aluminosilicate Fiber |

|---|---|---|

| Thermal Conductivity (W/m·K) | 0.07 @ 600°C | 0.12 @ 600°C |

| Maximum Service Temperature | >1300°C | ~1100°C |

| Mechanical Strength (MPa) | ≥3.0 | 1.5 - 2.0 |

| Typical Layer Thickness (mm) | 45 – 60* | 60 – 78* |

*Thickness ranges are typical; Sunrise vermiculite boards allow reduction by 10-18 mm while maintaining insulation performance.

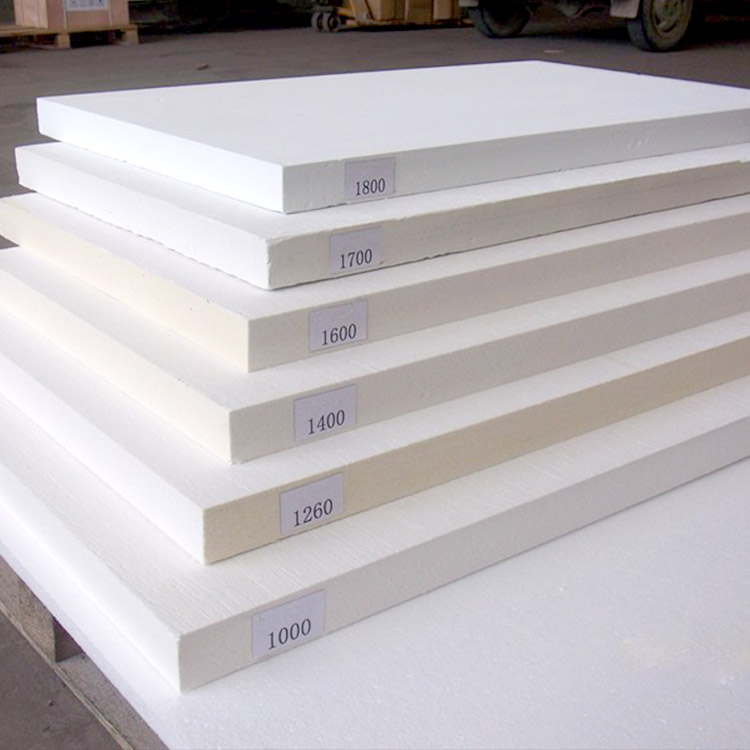

Sunrise’s vermiculite-based insulation board exemplifies material innovation tailored to the demanding thermal environment of steel ladles. Featuring a natural laminar structure, this board combines low thermal conductivity (~0.07 W/m·K at 600°C) with excellent mechanical durability and stability over prolonged thermal cycles. Its service temperature exceeds 1350°C, making it ideal for high-temperature lining without compromising lifespan.

By optimizing proprietary formulations and manufacturing processes, Sunrise’s product enables a reduction in insulation thickness by 10 to 18 mm compared to conventional materials. This “thinner but better” concept translates into a remarkable steel ladle outer shell temperature drop of up to 50°C under working conditions, thereby reducing heat losses and improving thermal efficiency significantly.

A leading steel producer in East Asia implemented Sunrise vermiculite ladle insulation boards across 12 ladles in continuous casting operations. Post-installation monitoring over 6 months showed:

To fully leverage the performance benefits of vermiculite-based insulation, strict adherence to installation protocols is essential. Key considerations include:

Recognizing the diversity in ladle geometry, operational regimes, and thermal requirements, Sunrise offers tailored vermiculite insulation solutions calibrated to client-specific process parameters. This bespoke approach ensures an optimal balance between material thickness, thermal insulation, mechanical resilience, and longevity — empowering steelmakers to align with stringent sustainability goals while improving operational efficiency.

Ready to optimize your ladle insulation system for cutting-edge energy efficiency and longevity? Get your personalized steel ladle insulation optimization plan today and take the first step toward greener, cost-effective steelmaking.